Embark on a journey to achieve an unparalleled level of automotive perfection with our comprehensive guide on How to Clay Bar Your Car for an Ultra-Smooth Finish. This process, often overlooked, is the secret weapon in a detailer’s arsenal, transforming a seemingly clean surface into a glass-like canvas. Prepare to discover the meticulous steps and essential knowledge that will elevate your car’s appearance and paint health to extraordinary new heights.

Our exploration delves into the fundamental purpose of clay barring, revealing how it effectively lifts embedded contaminants that washing alone cannot remove. We will meticulously detail the types of grit, grime, and environmental fallout that a clay bar can expertly tackle, from industrial fallout to tree sap. Understanding the benefits of this process means appreciating the dramatic improvement in paint texture and the enhanced durability of subsequent protective coatings.

Furthermore, we will equip you with a complete list of the necessary tools and materials, ensuring you are fully prepared for this transformative detailing step.

Understanding the Clay Bar Process

Clay barring your vehicle is a crucial step in achieving a truly pristine and showroom-quality finish. It goes beyond what a typical wash and wax can accomplish by addressing microscopic contaminants that become embedded in your car’s paintwork. This process prepares the surface for subsequent detailing steps, ensuring maximum shine and protection.The fundamental purpose of clay barring a vehicle’s surface is to decontaminate and smooth it at a microscopic level.

Over time, your car’s paint accumulates various particles from the environment that bond to the clear coat. These contaminants, though often invisible to the naked eye, create a rough texture that hinders the reflectivity and smoothness of the paint. Clay barring effectively lifts and removes these bonded impurities, revealing the true, unblemished surface beneath.

Types of Contaminants Removed by Clay Bar

Clay barring is remarkably effective at removing a wide array of stubborn contaminants that adhere to your car’s paint. These can accumulate from everyday driving and exposure to the elements, dulling the finish and making it feel rough to the touch.The following are common types of contaminants that clay barring effectively removes:

- Industrial Fallout: Tiny particles of metal and chemical residue released from factories and industrial areas that settle on your car’s surface.

- Brake Dust: Microscopic particles of metal and composite materials from brake pads that are electrostatically attracted to painted surfaces.

- Rail Dust: Similar to industrial fallout, these are small metallic particles originating from train tracks and railway operations.

- Tree Sap and Tar: Sticky residues from trees and asphalt that can harden and become difficult to remove with regular washing.

- Bug Splatter: The remains of insects that can etch into the paint if left on for extended periods.

- Overspray: Unwanted paint particles from nearby painting projects that can land on your vehicle.

- Road Grime: A general term for the accumulation of dirt, mud, and other road debris that bonds to the paint.

Benefits of an Ultra-Smooth Finish

Achieving an ultra-smooth finish through clay barring offers numerous advantages that enhance both the appearance and longevity of your vehicle’s paintwork. This level of smoothness is the foundation for superior detailing results.The benefits of an ultra-smooth finish are significant:

- Enhanced Gloss and Shine: A smooth surface reflects light more uniformly, leading to a deeper, more brilliant shine. Contaminants scatter light, making the paint appear dull.

- Improved Wax and Sealant Performance: Waxes, sealants, and ceramic coatings bond much more effectively and durably to a clean, smooth surface. This leads to longer-lasting protection and a better aesthetic.

- Easier Cleaning: Once the paint is smooth, dirt and grime have fewer microscopic pores to adhere to, making subsequent washes quicker and more effective.

- Prevention of Further Damage: Embedded contaminants can contribute to paint degradation over time. Removing them with clay barring helps preserve the integrity of the clear coat.

- Superior Aesthetic Appeal: The visual difference between a lightly contaminated and a perfectly smooth surface is striking. The paint will look and feel significantly cleaner and more refined.

Essential Tools and Materials for Clay Barring

To effectively clay bar your vehicle and achieve the desired ultra-smooth finish, having the correct tools and materials is essential. Using the right products ensures a safe and efficient process that prevents damage to your paint.The following are the essential tools and materials required for clay barring:

| Item | Description |

|---|---|

| Clay Bar (or Clay Mitt/Towel) | The primary tool for removing contaminants. Clay bars come in various grades (fine, medium, aggressive) depending on the level of contamination. Clay mitts and towels offer a convenient alternative, especially for larger vehicles. |

| Lubricant (Clay Lube or Quick Detailer) | Crucial for creating a slippery surface between the clay and the paint, allowing the clay to glide without scratching. A dedicated clay lubricant is recommended, but a high-quality quick detailer can also serve this purpose. |

| Microfiber Towels | Multiple high-quality microfiber towels are needed for drying the area after lubrication, wiping away clay residue, and buffing the surface to a shine. |

| Bucket of Water (Optional but Recommended) | For rinsing the clay bar or mitt periodically, especially if it picks up significant debris, to prevent re-depositing contaminants. |

| Gloves (Optional) | To keep your hands clean and provide a better grip on the clay bar. |

Preparing Your Vehicle for Clay Bar Application

Before you can achieve that impeccably smooth, glass-like finish, a crucial preparatory step is essential: thoroughly preparing your vehicle’s paintwork. This stage is not merely about making the car look clean; it’s about ensuring the clay bar can work effectively and, more importantly, safely. Skipping this vital preparation can lead to unintended scratches and marring, undermining the very goal of a flawless finish.The foundation of a successful clay bar treatment lies in a pristine surface.

Any dirt, grit, or debris left on the paint can be picked up by the clay bar and dragged across the surface, acting like sandpaper. Therefore, a meticulous wash and dry are paramount to remove loose contaminants and create a clean canvas for the clay bar to glide over.

The Importance of a Thorough Wash

A comprehensive wash is the first line of defense against scratching during the claying process. It aims to lift and remove as much surface-level dirt, dust, road grime, and other particulate matter as possible. This significantly reduces the risk of these abrasive particles being caught by the clay bar and causing micro-scratches or swirl marks.A proper washing technique involves using a pH-neutral car shampoo, plenty of clean water, and two buckets – one for the soapy water and one for rinsing the wash mitt.

This “two-bucket method” prevents dirt from being transferred back onto the paintwork. Always wash from top to bottom, allowing gravity to carry the dirt away. Rinse thoroughly to ensure no soap residue remains.

The Drying Process

After washing, a careful drying process is equally important. Avoid using old, abrasive towels that can leave lint or scratches. Opt for high-quality, plush microfiber drying towels. Gently pat or blot the surface dry, rather than rubbing vigorously. Work systematically, section by section, to prevent water spots from forming, especially in warmer climates.

Ensure all crevices, door jambs, and panel gaps are dried as well, as trapped water can drip onto the paint later and necessitate re-drying.

Inspecting Paintwork for Embedded Contaminants

Once the vehicle is clean and dry, it’s time to inspect the paintwork for embedded contaminants that a regular wash might not remove. These contaminants are what the clay bar is designed to lift. Common culprits include industrial fallout, brake dust, tar, tree sap, and bug splatter.You can identify these contaminants by touch. Gently run your clean hand (or a plastic baggie over your hand for increased sensitivity) over the paint surface.

If it feels rough, gritty, or bumpy, it indicates embedded contaminants. Visually, these might appear as small, dark specks, or areas of dullness and discoloration. Pay close attention to horizontal surfaces like the hood, roof, and trunk, as well as the lower panels which are more exposed to road spray.

Pre-Clay Bar Preparation Checklist

To ensure you don’t miss any critical steps, use this checklist before you begin the clay barring process:

- Ensure the vehicle is parked in a shaded area, out of direct sunlight. The paint surface should be cool to the touch.

- Gather all necessary supplies: pH-neutral car shampoo, two wash buckets, wash mitts, microfiber drying towels, clay bar lubricant (or quick detailer), clay bar, and a clean microfiber towel for wiping away residue.

- Perform a thorough two-bucket wash of the entire vehicle, working from top to bottom.

- Rinse the vehicle completely to remove all soap residue.

- Dry the vehicle meticulously using plush microfiber drying towels, ensuring all water is removed from all surfaces, including crevices.

- Conduct a tactile inspection of the paintwork by running a clean hand or a plastic baggie over the surface to identify any roughness or embedded contaminants.

- Visually inspect for any stubborn spots of tar, sap, or bug residue that may require pre-treatment (though the clay bar will handle most).

- Ensure you have adequate clay bar lubricant on hand. This is critical for the clay bar to glide smoothly and prevent scratching.

Selecting the Right Clay Bar and Lubricant

![Is Clay Soil Acidic or Alkaline? [Soil pH Range Explained] - Grow Your Yard Is Clay Soil Acidic or Alkaline? [Soil pH Range Explained] - Grow Your Yard](https://carasantai.web.id/wp-content/uploads/2025/09/materials-needed-for-polymer-clay-earrin.jpg)

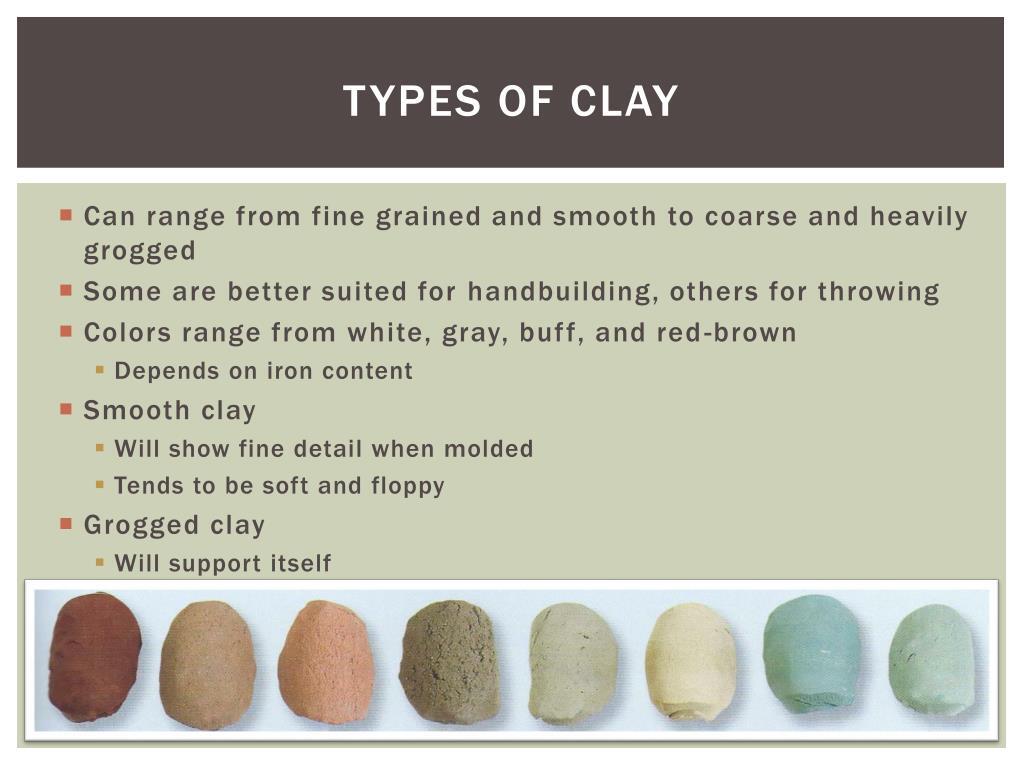

Choosing the appropriate clay bar and lubricant is paramount to achieving that coveted ultra-smooth finish without causing damage. The combination of these two elements dictates the effectiveness and safety of the claying process. Understanding their nuances will empower you to tackle different levels of surface contamination with confidence.The type of clay bar you select will depend on the severity of the contaminants on your vehicle’s paintwork.

Similarly, the lubricant plays a crucial role in facilitating the clay bar’s glide and preventing it from sticking or marring the surface.

Clay Bar Grades and Applications

Clay bars are categorized by their aggressiveness, designed to tackle varying degrees of bonded contaminants. It is crucial to select a grade that matches the contamination level to avoid unnecessary abrasion.

- Mild Grade Clay Bars: These are ideal for regular maintenance and for vehicles that are frequently washed and waxed. They are excellent for removing light surface contaminants such as fresh tar, bug residue, tree sap, and industrial fallout that haven’t had ample time to bond deeply. Mild clay bars offer a safer approach for enthusiasts and those new to claying, minimizing the risk of marring.

- Medium Grade Clay Bars: These offer a balance between cleaning power and safety. They are suitable for vehicles that experience moderate contamination, perhaps from occasional exposure to road grime, brake dust, or environmental pollutants. A medium grade can effectively remove contaminants that a mild clay might struggle with, without being overly aggressive.

- Aggressive Grade Clay Bars: These are the workhorses for heavily contaminated surfaces. They are designed to cut through stubborn, deeply bonded contaminants like heavy tar, paint overspray, rail dust, and severe industrial fallout. While highly effective, aggressive clay bars require more caution and are best used by experienced detailers. Their use can increase the risk of marring if not paired with proper lubrication and technique, often necessitating a follow-up polishing step.

Choosing an Appropriate Clay Lubricant

The clay lubricant acts as a barrier between the clay bar and the painted surface, allowing the clay to glide smoothly. Using the correct lubricant is as important as selecting the right clay bar, as it directly impacts the clay’s performance and the paint’s safety.

- Dedicated Clay Lubricants: These are specifically formulated to work with clay bars. They often contain polymers and surfactants that enhance glide, provide sufficient lubrication, and help lift contaminants away from the surface. They are generally the safest and most effective option.

- Quick Detailer Sprays: Many high-quality quick detailer sprays can double as clay lubricants. They offer a good balance of lubrication and cleaning properties. It’s advisable to use a quick detailer that is polymer-enhanced for better slickness.

- Water and Mild Soap Solution: In a pinch, a solution of water and a pH-neutral car wash soap can be used. However, this is generally less effective than dedicated lubricants and carries a higher risk of the clay sticking or marring, especially with more aggressive clay bars or on warmer days.

When selecting a lubricant, consider its slickness and its compatibility with your chosen clay bar. A lubricant that is too thin may not provide adequate glide, while one that is too thick might leave residue.

Function of a Lubricant in the Claying Process

The lubricant is indispensable in the claying process for several critical reasons, all contributing to a safe and effective outcome.The primary function of the lubricant is to create a slick surface. This slickness allows the clay bar to glide effortlessly over the paint. Without sufficient lubrication, the clay bar would drag, increasing friction. This increased friction can lead to the clay sticking to the surface, causing micro-scratches or marring.

Furthermore, the lubricant helps to encapsulate and lift the contaminants from the paintwork. As the clay bar moves across the lubricated surface, the contaminants are picked up by the clay, and the lubricant helps to suspend them, preventing them from being re-scratched back onto the paint.

The lubricant acts as a protective barrier, enabling the clay to shear contaminants away from the paint without causing damage.

Recommended Spray Patterns and Coverage for Lubricant Application

Proper application of the lubricant ensures that the clay bar has a consistently slick surface to work on, minimizing the risk of marring and maximizing efficiency.It is recommended to liberally spray the lubricant onto a small section of the vehicle’s surface at a time, typically no larger than 2×2 feet. This ensures that the area remains wet and slick throughout the claying process for that specific section.

A consistent, even spray pattern is key. Avoid applying too little lubricant, which can lead to the clay dragging. Conversely, while generous application is good, avoid excessive pooling of the lubricant, which can make it difficult for the clay to grip and lift contaminants effectively.The process involves spraying the lubricant, then gently gliding the clay bar over the lubricated area.

As you work, re-apply lubricant as needed to maintain that slick feel. It is also good practice to periodically rinse the clay bar itself with water or the lubricant to remove accumulated contaminants and maintain its effectiveness.

The Clay Bar Application Technique

Applying a clay bar to your vehicle’s paintwork is a crucial step in achieving that showroom-smooth finish. This process involves carefully gliding the clay bar over the surface to lift embedded contaminants that washing alone cannot remove. When performed correctly, it prepares the paint for polishing and protection, significantly enhancing its appearance and longevity.The technique for using a clay bar requires a gentle yet firm approach.

The goal is to allow the clay to do the work of grabbing and lifting contaminants without excessive pressure, which could otherwise mar the paint. Proper lubrication is key to ensuring the clay glides smoothly and safely across the surface.

Working the Clay Bar Over the Paint Surface

The correct method for working a clay bar over the paint surface involves a methodical, overlapping motion. Start with a small section of the vehicle, typically no larger than 2×2 feet, and apply a generous amount of lubricant to keep the surface wet. Gently glide the clay bar back and forth or in a circular motion over the lubricated area.

You will feel the clay begin to glide more freely as it picks up contaminants. Listen for a smooth gliding sound; if you hear a gritty or sticky sound, it indicates that more lubricant is needed or that the clay has become saturated and needs to be folded or replaced. It is important to work in a consistent direction within each section before moving to the next.

Folding and Kneading the Clay Bar

As the clay bar collects contaminants, its surface will become dirty and potentially gritty. To maintain its effectiveness and prevent scratching, it is essential to fold and knead the clay frequently. When the clay feels rough or you can see embedded grit on its surface, fold it in half, trapping the contaminants within the clay. Then, knead the clay like dough until a clean surface is exposed.

This process refreshes the clay, allowing it to continue safely lifting impurities from the paint. If the clay becomes extremely dirty or drops on the ground, it is best to discard it and use a fresh piece.

Maintaining Consistent Pressure and Motion

Consistent pressure and motion are vital for an effective and safe clay bar application. The pressure applied should be light to moderate, akin to the pressure you would use when wiping dust off a surface with a microfiber cloth. Excessive force can cause the clay to stick or even scratch the paint, especially if not properly lubricated. The motion should be smooth and controlled, typically in overlapping strokes.

Working in small sections and focusing on consistent technique within each section ensures that no area is missed and that the paint is treated evenly.

Procedure for Claying Different Vehicle Panels

Claying different vehicle panels follows the same fundamental principles but requires attention to the panel’s shape and accessibility.

- Hood: Start from one edge and work your way across, using overlapping strokes. Divide larger hoods into smaller, manageable sections.

- Roof: This is often the dirtiest area. Ensure ample lubrication and use long, sweeping motions. Be mindful of maintaining balance and reach.

- Doors: Work from top to bottom, paying attention to the contours and edges. The lower sections of doors often collect more road grime.

- Fenders and Bumpers: These areas are prone to road debris. Use careful, deliberate strokes, especially around any textured plastic or trim.

- Trunk Lid: Similar to the hood, work in a systematic manner, ensuring complete coverage.

- Windows (Glass Only): Some clay bars are safe for glass, which can remove stubborn water spots or tree sap. Always use ample lubricant and test in an inconspicuous area first.

It is recommended to work on one panel at a time, or even divide larger panels into smaller sections, especially if you are new to the process. Always ensure each section is thoroughly lubricated before claying and rinse or wipe down the panel as you move between sections or if the clay starts to drag.

Handling Contaminated Clay and Potential Issues

Proper handling of your clay bar is crucial to achieving that ultra-smooth finish and avoiding damage to your vehicle’s paintwork. As you work, the clay bar will inevitably pick up contaminants, and recognizing when it’s no longer effective or safe to use is a key skill for any detailer. Being aware of potential pitfalls and knowing how to address them will ensure a successful and damage-free clay barring experience.

Identifying When to Fold or Replace a Clay Bar

A clay bar is designed to lift and encapsulate contaminants from your paint. As it collects dirt, debris, and other particles, its surface will become visibly soiled and rough. Continuing to use a heavily contaminated clay bar can reintroduce these contaminants back onto your paint, leading to scratches.

- Visible Contamination: When the clay bar’s surface appears dull, discolored, or has embedded particles that are not easily released, it’s time to address it.

- Loss of Slickness: A clean clay bar glides smoothly over the lubricant. If you feel increased resistance or a gritty sensation, even with sufficient lubricant, the clay is likely saturated.

- Folding Technique: To refresh a moderately contaminated clay bar, fold it in on itself. This process brings a clean surface to the exterior. Continue folding until all sides of the clay bar are soiled, or until it becomes too small to handle effectively.

- Replacement Threshold: Once a clay bar can no longer be effectively folded to reveal a clean surface, or if it has become very small and difficult to grip, it is time to discard it and use a fresh one.

Consequences of Dropping a Clay Bar

Dropping a clay bar on the ground is a common mistake that can have significant negative consequences for your car’s paint. The clay bar’s primary function is to pick up microscopic contaminants, and the ground is a rich source of larger, abrasive particles.

“Once a clay bar touches the ground, it is compromised and should be discarded immediately. Its ability to safely pick up contaminants is lost, and it will inevitably cause scratches.”

The particles embedded in a dropped clay bar, such as sand, grit, and other debris, are much larger and more abrasive than the contaminants you are trying to remove from your paint. When you attempt to use a dropped clay bar, these embedded particles will act like sandpaper, creating marring and deep scratches in your clear coat. This damage often requires significant paint correction, such as compounding and polishing, to rectify.

Solutions for Common Clay Barring Mistakes

Even experienced detailers can encounter issues during the clay barring process. Knowing how to identify and correct these problems will save you time and prevent permanent paint damage.

- Paint Marring: If you notice light, hazy scratches (marring) on your paint after clay barring, it’s usually due to using a contaminated clay bar or insufficient lubrication. The solution is to perform a paint correction process. This typically involves using a compound to remove the deeper scratches, followed by a polish to refine the finish and restore gloss.

- Residue: Occasionally, a clay bar may leave behind small pieces of residue, especially if it’s been overused or folded improperly. This residue can often be removed with a quick detailer spray and a clean microfiber towel. For more stubborn residue, a light pass with a fresh clay bar and ample lubricant can also be effective.

- Uneven Application: If you notice an area that feels rougher than others, it might be due to inconsistent pressure or insufficient lubricant in that spot. Go back over the area with fresh lubricant and a clean section of your clay bar, ensuring even strokes and light pressure.

Safe Disposal of Used Clay Bars

Proper disposal of used clay bars is important for environmental reasons and to prevent accidental reuse. Because they are saturated with contaminants, they should not be treated as regular household waste without some consideration.

- Contaminant Encapsulation: The clay bar has effectively encapsulated harmful contaminants. Once discarded, it should be kept away from areas where it could leach these contaminants.

- Bagging and Sealing: The safest method for disposal is to place the used clay bar into a sealable plastic bag. Ensure the bag is securely closed to prevent any loose particles from escaping.

- Discarding: Once bagged, the clay bar can be placed in your regular household trash. However, some may prefer to dispose of it in a separate, clearly marked waste bin to ensure it’s not accidentally picked up for reuse.

- Recycling Considerations: Clay bars are typically not recyclable due to their composition and the contaminants they hold. Therefore, landfill disposal is the standard practice.

Post-Clay Bar Surface Treatment

Once you’ve completed the clay barring process, your vehicle’s paintwork is in a pristine state, free from contaminants and incredibly smooth. However, this smoothness also means the surface is now highly receptive, and it’s crucial to follow up with appropriate treatments to maintain this newfound finish and protect it from the elements. This stage is about sealing in the smoothness and ensuring the longevity of your hard work.The primary reason for washing your car again after clay barring is to remove any residual clay lubricant or residue that might have been left behind.

While many lubricants are designed to be safe, they can sometimes leave a faint film. More importantly, the clay bar itself, having picked up contaminants, will have microscopic particles on its surface. A thorough rinse and wash ensure these are completely removed, preventing them from being smeared or reintroducing imperfections.

Drying the Vehicle

Proper drying is paramount after washing to prevent water spots, which are mineral deposits left behind as water evaporates. These spots can mar the perfectly smooth finish you’ve achieved. Employing the right techniques and tools will ensure a spot-free shine.Here are the recommended steps for drying your car to prevent water spots:

- Begin drying immediately after the final rinse. Do not let the car air dry.

- Use high-quality microfiber drying towels. These are highly absorbent and soft, minimizing the risk of scratching the paint. Have several towels on hand so you can switch to a dry one as needed.

- Work from the top of the vehicle downwards. This ensures that any water dripping from higher sections doesn’t re-wet already dried areas.

- Gently pat or blot the surface with the towel, rather than rubbing vigorously. This technique lifts water more effectively and reduces friction.

- For crevices, door jambs, and around trim, use a dedicated drying aid or a separate, smaller microfiber towel to absorb trapped water.

- Consider using a leaf blower or a car dryer (a high-velocity air blower specifically designed for cars) to blow water out of tight areas and off large panels. This is particularly effective for eliminating hidden water that can drip later.

Applying Sealants or Waxes

With a clean, dry, and ultra-smooth surface, it’s the ideal time to apply a protective layer. Sealants and waxes not only enhance the gloss but also provide a barrier against UV rays, environmental fallout, and future contaminants, making subsequent washes easier.The choice between a sealant and a wax depends on your desired durability and finish.

- Paint Sealants: These are synthetic products that typically offer longer-lasting protection (often 6-12 months or more) and a slick, reflective shine. They bond chemically with the paint surface.

- Waxes: Traditionally made from carnauba or other natural ingredients, waxes offer a warm, deep glow and are often easier to apply and remove. Their durability is generally shorter (typically 1-3 months).

For an ultra-smooth finish achieved through clay barring, a paint sealant is often recommended for its superior durability and ability to further enhance the slickness. However, a high-quality carnauba wax can also provide a beautiful finish.

Post-Clay Bar Care Sequence

To ensure optimal results and maintain the smooth finish achieved after clay barring, follow this sequence of post-clay bar care steps:

- Wash: Perform a thorough wash using a pH-neutral car shampoo and the two-bucket method to remove any residual clay lubricant or debris.

- Rinse: Rinse the vehicle completely, ensuring no soap residue remains.

- Dry: Dry the vehicle meticulously using high-quality microfiber towels and the blotting technique, starting from the top and working down. Use a leaf blower or car dryer for intricate areas.

- Decontaminate (Optional but Recommended): For an extra layer of protection and to prepare the surface for bonding, consider an IPA (Isopropyl Alcohol) solution or a dedicated panel wipe. This removes any remaining oils or residues from the wash and drying process, ensuring maximum adhesion for your chosen protectant. A 1:1 dilution of IPA and distilled water is a common choice. Apply with a clean microfiber towel and wipe off immediately.

- Apply Protection: Apply your chosen paint sealant or wax according to the manufacturer’s instructions. Work in small sections, ensuring even coverage.

- Buff Off: Gently buff off any excess product with a clean, dry microfiber towel to reveal the glossy, protected finish.

- Allow to Cure: If using a sealant, allow it adequate time to cure before exposing the vehicle to harsh weather or washing it again. Check the product’s specifications for curing times.

By diligently following these post-clay bar treatment steps, you will not only protect your vehicle’s paintwork but also maximize the visual appeal and tactile sensation of its ultra-smooth finish.

Visualizing the Ultra-Smooth Finish

After meticulously working through the clay barring process, the transformation of your vehicle’s surface is not just felt, but profoundly seen. This stage is where the fruits of your labor become undeniably apparent, revealing a level of finish that speaks volumes about the care taken. Understanding how to recognize this pristine state is key to appreciating the full impact of clay barring.The tactile sensation is the most immediate indicator of a successfully clayed surface.

A properly decontaminated finish will feel incredibly slick and glassy to the touch, almost like polished glass. When you run your hand across the paint, there should be no hint of roughness, grit, or drag. It’s a smooth, effortless glide that signifies all bonded contaminants have been lifted. This newfound smoothness is the foundation upon which a superior shine is built.

The Enhanced Reflectivity of Paint

The ultra-smooth finish achieved through clay barring dramatically enhances the paint’s ability to reflect light. When the surface is free of microscopic contaminants like industrial fallout, rail dust, and overspray, light can travel across the paint in a more uniform and direct manner. This lack of interruption allows for a clearer, sharper, and more intense reflection of light sources, leading to a deeper gloss and a more vibrant appearance of the paint color.

Visual Cues of Successful Clay Barring

Several visual cues will confirm that your clay barring efforts have been successful. These indicators range from subtle changes in gloss to a more profound depth of color.

- Increased Gloss and Shine: The most noticeable change will be a significant boost in the overall gloss and shine of your vehicle’s paint. It will appear wetter and more luminous than before.

- Deeper Color Saturation: The true color of your paint will appear richer and more saturated. The clay bar removes the dulling layer of contaminants, allowing the inherent vibrancy of the paint to shine through.

- Sharper Reflections: Reflections in the paint will become crisper and more defined. You’ll be able to see details in reflected objects with greater clarity.

- “Wet Look” Appearance: A properly clayed surface often exhibits a desirable “wet look,” where the paint appears as if it’s perpetually covered in a thin layer of water, even when dry.

- Absence of Swirl Marks (in conjunction with polishing): While clay barring itself doesn’t remove scratches or swirl marks, it prepares the surface for polishing. However, a clean surface will make any existing imperfections more visible, allowing for more effective correction during the polishing stage.

Light Interaction with an Ultra-Smooth, Claimed Surface

Imagine light as a gentle wave. On a surface riddled with microscopic contaminants, these waves hit obstacles, scattering and diffusing, resulting in a dull, muted appearance. However, on an ultra-smooth, clayed surface, these light waves flow unimpeded. They strike the paint and bounce back in a highly organized, coherent manner. This creates a dazzling display where light seems to pour across the surface, amplifying its inherent color and depth.

The reflections are so pure that the paint appears almost liquid, a mirror-like finish that captivates the eye. This is the ultimate testament to a successful clay bar application, a finish so smooth it actively plays with light to showcase its brilliance.

Last Point

As we conclude our detailed exploration of How to Clay Bar Your Car for an Ultra-Smooth Finish, the path to a truly pristine vehicle is clear. By understanding and applying the techniques discussed, you have unlocked the ability to not only visually enhance your car’s paint but also to protect its integrity against the elements. This meticulous process is more than just a detailing step; it’s an investment in your vehicle’s longevity and aesthetic appeal, ensuring that its finish remains not just clean, but exceptionally smooth and radiant for years to come.