How to Clay Bar Your Car’s Glass sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with formal and friendly language style and brimming with originality from the outset.

This comprehensive guide delves into the intricate process of glass clay barring, a crucial yet often overlooked step in achieving a truly pristine vehicle. We will explore the transformative benefits of a smooth, contaminant-free glass surface, understanding precisely what types of stubborn impurities can be effectively banished. Furthermore, we will illuminate why a specialized glass clay bar often proves superior to its automotive body counterpart, ensuring optimal results for your vehicle’s most transparent surfaces.

Introduction to Glass Clay Bar Detailing

Clay barring your car’s glass is a specialized detailing process designed to remove stubborn contaminants that washing alone cannot address. This meticulous approach ensures your glass is not only visibly clean but also microscopically smooth, enhancing clarity and safety. By lifting embedded particles, clay barring prepares the glass surface for optimal protection and performance.The primary purpose of clay barring car glass is to achieve a perfectly smooth and contaminant-free surface.

This smoothness is crucial for several reasons, including improved visibility, enhanced performance of windshield wipers, and better adhesion for sealants or coatings. A glass surface that feels slick to the touch, rather than gritty or rough, indicates successful contaminant removal.

Benefits of a Smooth, Contaminant-Free Glass Surface

A glass surface that has been properly clay barred offers significant advantages for both aesthetics and functionality. The removal of bonded contaminants leads to a noticeable improvement in the visual clarity of your windows, which is especially important for driving safety. Furthermore, the smooth surface created by clay barring can enhance the effectiveness of other automotive care products.The benefits include:

- Enhanced Visibility: Removing embedded grime, water spots, and industrial fallout dramatically improves how clearly you can see through your windshield and windows, particularly in challenging lighting conditions or during inclement weather.

- Improved Wiper Performance: Contaminants on glass can cause windshield wipers to chatter, skip, or streak. A smooth surface allows wipers to glide effortlessly, clearing water more effectively and extending their lifespan.

- Superior Protection Application: When applying glass sealants, ceramic coatings, or even waxes, a clean and smooth surface ensures better bonding and longer-lasting protection. This leads to superior water beading and easier cleaning in the future.

- Aesthetic Appeal: Beyond safety, a truly clean and smooth glass surface contributes to the overall polished appearance of your vehicle.

Types of Contaminants Removed from Car Glass

Over time, car glass accumulates a variety of embedded particles that bond to the surface and cannot be removed by regular washing. Clay barring is effective at lifting these tenacious contaminants, restoring the glass to its original smooth state.Common contaminants that can be removed include:

- Industrial Fallout: Microscopic particles of metal, brake dust, and other airborne pollutants from industrial areas or busy roads that embed into the glass.

- Rail Dust: Tiny metallic particles often found near train tracks, which can bond strongly to glass surfaces.

- Tree Sap and Tar: Sticky residues from trees or road construction that harden and become difficult to remove with standard cleaners.

- Bug Splatter: The hardened remains of insects that, if left untreated, can etch into the glass surface.

- Hard Water Spots: Mineral deposits left behind after water evaporates, often appearing as white or cloudy spots, especially in areas with hard water.

- Overspray: Paint or other chemical overspray from nearby construction or painting projects.

Dedicated Glass Clay Bar Versus Automotive Body Clay

While automotive body clay is designed to remove contaminants from paintwork, it is often recommended to use a dedicated glass clay bar for detailing car glass. This distinction is important because glass and paint have different surface properties and are susceptible to different types of contaminants.Using a dedicated glass clay bar offers several advantages:

- Formulation: Glass clay bars are typically formulated with a slightly different abrasive quality or lubrication properties to effectively tackle the specific types of bonded contaminants found on glass without causing damage.

- Aggressiveness: Some automotive body clays can be too aggressive for glass, potentially leading to micro-scratches if not used with extreme care and the correct lubrication. A glass clay bar is generally formulated for a safer interaction with the glass surface.

- Lubrication Compatibility: The lubricants used with glass clay bars are optimized for glass, ensuring sufficient slip and reducing the risk of marring the surface.

- Efficiency: A dedicated tool can be more efficient in removing glass-specific contaminants, leading to better results in less time.

It is crucial to always use a dedicated lubricant specifically designed for clay barring glass to ensure a safe and effective process. This lubricant creates a barrier between the clay and the glass, allowing the clay to glide smoothly and lift contaminants without scratching.

Essential Tools and Materials for Glass Clay Barring

Successfully and safely claying your car’s glass requires a specific set of tools and materials. These items are designed to work in conjunction with the clay bar, ensuring a smooth, effective decontamination process without causing damage to the glass surface. Having the right supplies readily available will streamline the detailing process and yield superior results.This section Artikels the necessary equipment and consumables, providing clear descriptions and guidance on their selection and application.

Understanding the purpose of each item is key to achieving a flawless finish.

Required Items for Glass Clay Barring

To effectively and safely decontaminate your vehicle’s glass, a curated selection of items is essential. These are not merely optional additions but fundamental components of the glass clay barring process.

- Clay Bar for Glass: Specifically designed clay bars for glass are softer and formulated to be safe for automotive glass. They are crucial for lifting embedded contaminants without scratching.

- Clay Lubricant: A specialized lubricant is indispensable. It creates a slick surface, allowing the clay bar to glide smoothly over the glass, preventing friction and potential marring.

- Microfiber Towels: High-quality, plush microfiber towels are needed for drying, buffing, and wiping away any lubricant residue. Their softness ensures they won’t scratch the glass.

- Gloves: Wearing nitrile or latex gloves protects your hands from the clay and lubricant, and also helps to prevent transferring oils from your skin to the glass, which could affect the clay’s performance.

- Spray Bottle: For applying the clay lubricant evenly and efficiently across the glass surface.

- Bucket (Optional): While not strictly necessary for glass, a bucket can be useful for rinsing the clay bar if it becomes heavily contaminated, though for glass, a quick wipe on a microfiber is often sufficient.

Function of Each Tool and Material

Each component in a glass clay barring kit plays a distinct and vital role in the overall effectiveness and safety of the detailing process. Understanding these functions ensures proper usage and optimal outcomes.

- Clay Bar for Glass: This is the primary decontamination tool. Its pliable, slightly abrasive surface molecularly bonds with and lifts contaminants like road film, tree sap, bug splatter, and industrial fallout that are embedded in the microscopic pores of the glass.

- Clay Lubricant: The lubricant acts as a barrier between the clay bar and the glass surface. It reduces friction, allowing the clay to slide effortlessly. Without sufficient lubrication, the clay can stick, drag, and potentially cause scratches or marring.

- Microfiber Towels: These are used for several purposes: to dry the glass before claying, to wipe away excess lubricant during the process, and for the final buffing to reveal a crystal-clear finish. The soft fibers trap dirt and debris, preventing them from being dragged across the glass.

- Gloves: Essential for hygiene and to maintain the integrity of the detailing process. They protect your skin and prevent skin oils from interfering with the clay’s ability to grab contaminants.

- Spray Bottle: Allows for a controlled and even application of the lubricant. A fine mist ensures the entire working area is adequately covered, which is critical for preventing friction.

- Bucket: Primarily used in paint claying to rinse the clay bar when it picks up excessive debris. For glass, it’s less critical, but if the clay becomes very dirty, a quick rinse can help maintain its effectiveness.

Suitable Lubricants for Glass Clay Barring

The choice of lubricant is paramount for the safe and effective claying of automotive glass. It must provide adequate slip to prevent marring while also being compatible with glass and detailing products.The most effective lubricants for glass clay barring are specifically formulated detailing sprays. These products are designed to offer superior lubricity and often contain mild cleaning agents that can aid in the decontamination process.

While some general-purpose detailing sprays can be used, dedicated clay lubricants are generally recommended for their optimized performance. Water alone is insufficient as it does not provide the necessary slickness to prevent the clay from binding and potentially scratching the glass.A good clay lubricant will create a slippery surface that allows the clay bar to glide smoothly. This slickness is crucial for lifting contaminants without dragging them across the glass, which could lead to micro-scratches.

Checklist of Required Supplies

To ensure you are fully prepared for the glass clay barring process, refer to this comprehensive checklist of all necessary items. Having everything on hand before you begin will make the detailing session more efficient and enjoyable.

| Item | Quantity | Notes |

|---|---|---|

| Clay Bar for Glass | 1 | Ensure it’s specifically designed for glass. |

| Clay Lubricant | 1 bottle (approx. 16 oz) | Dedicated clay lubricant or high-quality detailing spray. |

| Microfiber Towels | 3-4 | Plush, high-quality towels for drying and buffing. |

| Nitrile or Latex Gloves | 1 pair | For hand protection. |

| Spray Bottle | 1 | For applying lubricant. |

| Bucket (Optional) | 1 | For rinsing clay if heavily soiled. |

Preparing Your Vehicle’s Glass for Claying

Before you can effectively use a clay bar on your car’s glass, a thorough preparation process is essential. This ensures that the clay bar can work efficiently by removing embedded contaminants without encountering loose debris that could cause scratching. A clean surface allows the clay to glide smoothly, maximizing its effectiveness and contributing to a superior finish.The initial step in preparing your vehicle’s glass for claying is a comprehensive wash and dry.

This removes the bulk of loose dirt, dust, and grime that could otherwise interfere with the claying process. Following a proper wash with a meticulous drying technique prevents water spots and ensures a clean canvas for the next stages of detailing.

Glass Cleaning for Surface Contaminant Removal

To effectively prepare your glass for claying, a detailed cleaning process is necessary to lift and remove surface dirt and debris. This goes beyond a simple rinse and involves using appropriate cleaning agents to break down road film, bug splatter, and other common automotive residues. The goal is to create a surface that is as free from loose particles as possible.The cleaning process typically involves a two-bucket wash method with a pH-neutral car shampoo.

Use a dedicated wash mitt or microfiber towel specifically for glass to avoid cross-contamination with paintwork cleaners. Thoroughly agitate the entire glass surface, paying attention to edges and corners where dirt tends to accumulate. After washing, rinse the glass completely to remove all soap residue.

Inspecting Glass for Visible Contaminants

After washing and drying, a careful inspection of the glass is crucial to identify any remaining embedded contaminants that the clay bar will target. This step allows you to gauge the extent of contamination and ensure you haven’t missed any areas. Spotting these imperfections before claying helps in achieving a perfectly smooth finish.Methods for inspection include:

- Visual Scan: Shine a bright light source (like a flashlight or LED work light) across the glass at various angles. This will highlight imperfections, water spots, and embedded particles that might not be obvious in normal lighting.

- Touch Test: Gently run your fingertips across the dry glass surface. You will be able to feel rough spots, bumps, or gritty textures that indicate embedded contaminants.

- Plastic Bag Method: Cover your hand with a thin plastic bag or a glove and carefully slide it across the glass. This technique amplifies the sensation of any roughness, making even minor contaminants more noticeable.

Working in a Suitable Environment for Detailing

The environment in which you perform glass claying significantly impacts the outcome and the safety of the process. Working in suboptimal conditions can lead to scratching, ineffective cleaning, and premature drying of your detailing lubricants. Choosing the right location is a key aspect of professional detailing.Considerations for a suitable detailing environment include:

- Shade: Always work in a shaded area, away from direct sunlight. Direct sun can heat the glass surface rapidly, causing detailing products to dry too quickly and potentially leaving streaks or marring.

- Moderate Temperatures: Avoid extreme temperatures, both hot and cold. Very hot conditions can cause products to evaporate too fast, while very cold temperatures can make clay stiff and difficult to work with. Ideal temperatures are typically between 50°F and 85°F (10°C and 30°C).

- Low Wind: Minimize exposure to wind, as it can blow dust and debris onto the wet glass surface, reintroducing contaminants that you’ve just removed.

- Cleanliness: Ensure the surrounding area is as clean as possible. Avoid working near dusty construction sites or areas with heavy traffic that kicks up dirt.

The Clay Bar Application Process on Glass

Now that your vehicle’s glass is properly prepared and you have all your essential tools and materials ready, it’s time to delve into the core of glass detailing: the clay bar application process. This stage is where the magic truly happens, as the clay bar actively lifts and encapsulates embedded contaminants, leaving your glass incredibly smooth and clean. Achieving optimal results requires a systematic approach, focusing on technique, lubrication, and careful observation.The clay bar application is a delicate yet effective process designed to physically remove bonded contaminants from the glass surface that washing alone cannot address.

It’s crucial to understand that this is not an abrasive process, but rather a chemical and mechanical one where the clay acts as a magnet for microscopic debris. By following the correct steps, you ensure that the clay works efficiently without causing any damage, leaving your glass with a pristine, like-new finish.

Correct Clay Bar Technique

Applying the clay bar to your car’s glass involves a specific technique to ensure thorough cleaning without scratching. The goal is to glide the clay smoothly over the lubricated surface, allowing it to pick up contaminants. It’s important to use light to moderate pressure, letting the clay do the work. Avoid pressing down too hard, as this can embed contaminants deeper into the clay or, in rare cases, cause streaking if not done carefully.

Work in small, manageable sections, typically no larger than 2×2 feet, to ensure consistent coverage and to avoid the lubricant drying out before you can clay that area.

Maintaining Adequate Lubrication

Lubrication is the cornerstone of a safe and effective clay bar process. Without sufficient lubrication, the clay bar can stick to the glass, creating friction and potentially causing scratches. The clay lubricant, often a dedicated spray detailer or a mixture of car wash soap and water, creates a slippery barrier between the clay and the glass. You must reapply the lubricant frequently to the section you are working on, as well as to the clay bar itself, before each pass.

A good rule of thumb is to spray generously and ensure the surface remains visibly wet at all times.

“Adequate lubrication is paramount to a scratch-free clay bar experience. Never let the clay touch dry glass.”

Recognizing Effective Contaminant Removal

The feel and sound of the clay bar are your primary indicators that it is effectively removing contaminants. Initially, as you glide the clay over a dirty section of glass, you will feel and hear a noticeable drag or grittiness. The clay will feel like it’s catching or sticking slightly to the surface. As you continue to work the lubricated area, this grittiness will gradually disappear.

The clay will begin to glide smoothly and almost silently across the glass, indicating that the majority of the bonded contaminants have been lifted.When the clay bar starts to feel smooth and slick, it signifies that the surface is clean. The sound will change from a subtle scrubbing or tearing noise to a gentle, consistent glide. This transition is your cue to move to the next section or to inspect the clay for accumulated debris.

Handling Stubborn Contaminants

Some contaminants, such as stubborn tar spots, tree sap residue, or industrial fallout, may require a bit more attention. For these areas, you can increase the pressure slightly, but always with ample lubrication. If a contaminant proves particularly resistant, you can try working it with a corner of the clay bar or folding the clay to expose a fresh surface.

In very rare and severe cases, a specialized tar and bug remover or a more aggressive clay bar might be necessary, but for most situations, patience and consistent lubrication will prevail.

“For persistent contaminants, increase pressure gradually and ensure continuous lubrication. Fold the clay to expose a clean surface.”

Step-by-Step Procedure for Claying a Single Glass Panel

To ensure a methodical and thorough claying of your car’s glass, follow this step-by-step procedure for each panel:

- Lubricate the Area: Generously spray the chosen section of glass with your clay lubricant. Ensure the entire area is well-covered and glistening.

- Prepare the Clay Bar: Take a portion of your clay bar and flatten it into a pad-like shape. This increases the surface area in contact with the glass and makes it easier to handle.

- Initial Pass: Gently place the flattened clay bar onto the lubricated glass surface. Begin gliding the clay back and forth or in a circular motion with light to moderate pressure. You should feel and hear the initial resistance as it lifts contaminants.

- Observe and Feel: Pay close attention to the feedback from the clay bar. As it cleans the surface, the grittiness will diminish, and the clay will glide more smoothly.

- Re-lubricate and Fold: Before making another pass, re-lubricate the area generously. If the clay bar has picked up a significant amount of dirt (it will appear discolored and feel rough), fold it in on itself to expose a clean surface. This prevents you from re-depositing contaminants back onto the glass.

- Continue Working: Repeat steps 3-5, working across the entire panel. Ensure you cover all areas, including edges and corners.

- Inspect the Clay: Periodically, check the condition of your clay bar. If it becomes heavily soiled or feels very rough, it’s time to discard that portion and use a fresh piece or a new clay bar.

- Wipe Down: Once the entire panel feels smooth to the touch and the clay glides freely, wipe away any remaining lubricant residue with a clean microfiber towel.

- Inspect for Clarity: Visually inspect the glass to ensure no streaks or marring remain. If any are present, a light re-application of lubricant and a gentle pass with a clean section of clay may be needed.

Handling Different Types of Glass Contaminants

Successfully cleaning your car’s glass with a clay bar involves understanding and effectively addressing various types of contaminants that can adhere to the surface. These substances, often microscopic, can create a rough texture and impede clarity, even after washing. Recognizing them and employing the correct techniques ensures a smooth, pristine finish without causing damage.The clay bar’s magic lies in its ability to encapsulate and lift these bonded contaminants from the glass surface.

However, some contaminants are more stubborn than others and may require specific approaches. It’s crucial to be patient and methodical to achieve the best results and avoid unintended consequences like scratches.

Common Glass Contaminants

Various elements in our environment can deposit onto your car’s glass, creating a film that diminishes visibility and makes cleaning difficult. Identifying these culprits is the first step in effective removal.

- Rail Dust: These are tiny metallic particles, often reddish-brown, that originate from the friction of train wheels on rails. They are highly magnetic and tend to embed themselves firmly into the glass surface.

- Industrial Fallout: This category encompasses a broad range of airborne pollutants emitted from factories, construction sites, and other industrial activities. These particles can be metallic, chemical, or particulate matter, and they can create a dull, grimy layer on your glass.

- Overspray: This refers to paint, primer, or sealant that has been sprayed in the vicinity of your vehicle and has settled onto the glass. It can be particularly challenging to remove, especially if it has cured.

- Tree Sap and Bug Splatter: While organic, these can become hardened and baked onto the glass by the sun, making them difficult to remove with conventional washing.

- Water Spots: These are mineral deposits left behind after water evaporates. While often removable with standard cleaners, heavily etched water spots can be a challenge.

Approaches to Removing Embedded Contaminants

When contaminants have become deeply embedded in the glass, a more deliberate approach with the clay bar is necessary. The key is to provide adequate lubrication and apply consistent, gentle pressure.The process involves ensuring the glass is thoroughly lubricated with a dedicated glass cleaner or clay lubricant. Then, the clay bar should be worked over the contaminated area in straight lines or a back-and-forth motion, rather than circular.

This minimizes the risk of creating marring. Periodically inspect and fold the clay to expose a clean surface, preventing the embedded contaminants from being dragged across the glass and causing scratches. For particularly stubborn areas, you might need to make multiple passes with the clay.

Addressing Stubborn Contaminants

In instances where the clay bar alone does not fully remove embedded contaminants, further steps may be required. It’s important to assess the situation carefully before proceeding.If a contaminant persists after several passes with the clay bar, it might be too deeply bonded or have altered the glass surface. In such cases, consider using a specialized glass polish. These polishes contain very fine abrasives that can gently level the glass surface, removing the remaining contaminant without causing significant material loss.

Always test a small, inconspicuous area first. If the contaminant is a very stubborn overspray, a mild chemical remover designed for paint overspray might be an option, but it’s crucial to ensure it’s safe for automotive glass and to follow the product instructions precisely.

Potential for Etching or Scratching

The improper use of a clay bar on glass can lead to unintended damage, primarily in the form of etching or scratching. Understanding these risks is paramount to a successful detailing process.

- Scratching: This occurs when abrasive particles are trapped between the clay bar and the glass surface, and then dragged across. This is often caused by insufficient lubrication, using a dirty clay bar, or applying excessive pressure. The particles that cause scratching are often the very contaminants you are trying to remove if they are not properly encapsulated by the clay.

- Etching: While less common with clay barring itself, etching can occur if aggressive chemicals are used to remove contaminants without proper dilution or if acidic contaminants are left on the glass for extended periods and then aggressively scrubbed. For instance, some industrial fallout can be acidic and, if left to sit, can begin to etch the glass. Clay barring can sometimes reveal these pre-existing etch marks.

“Adequate lubrication is the most critical factor in preventing scratches when clay barring any surface, especially glass.”

If you notice a scratch, it’s important to assess its depth. Minor marring might be correctable with a glass polish. Deeper scratches, however, may be permanent and require professional attention or even glass replacement. Always work gently and methodically to minimize the risk of damage.

Post-Clay Bar Glass Care and Protection

After the meticulous process of clay barring your car’s glass, a crucial phase of care and protection begins. This ensures the pristine finish achieved is maintained and enhances the longevity and clarity of your glass surfaces. Proper post-treatment not only safeguards against future contaminants but also contributes to a superior driving experience by maintaining optimal visibility.Following the clay bar application, your glass will feel exceptionally smooth and free from embedded contaminants.

This is the ideal moment to introduce protective measures that will keep it that way. The subsequent steps are designed to lock in that smoothness and shield the glass from the elements.

Glass Rinsing and Drying

The initial step after claying is to thoroughly rinse the glass to remove any residual clay lubricant and loosened contaminants. This is typically followed by a meticulous drying process to prevent water spots and streaks, which would detract from the newly achieved clarity.A high-quality microfiber drying towel is essential for this stage. Gently pat and wipe the glass, working from top to bottom.

For areas where water might pool, such as around window seals, a separate, dedicated drying aid or a detail brush can be used to carefully wick away moisture. Avoid using abrasive cloths or paper towels, as these can reintroduce scratches or leave lint.

Surface Inspection for Smoothness

Once the glass is clean and dry, a thorough inspection is vital to confirm the success of the clay barring process. This involves a tactile and visual assessment to ensure all imperfections have been removed.Run your clean hand over the glass surface. It should feel completely smooth and slick, without any grittiness or rough patches. Visually, the glass should appear exceptionally clear, with no haziness or streaking.

If any areas feel less than perfect, a light re-application of lubricant and a gentle pass with the clay bar in that specific spot may be necessary, followed by another rinse and dry.

Glass Protection Options

With the glass perfectly prepped, applying a protective layer is highly recommended. This layer acts as a barrier against future environmental damage and makes subsequent cleaning much easier. Several excellent options are available, each offering different levels of durability and performance.The primary goal of these protective treatments is to create a hydrophobic surface. This means water will bead up and roll off the glass more readily, taking dirt and grime with it.

This significantly improves visibility during rain and reduces the need for frequent, aggressive cleaning.

- Glass Sealants: These are polymer-based products that bond to the glass surface, offering protection for several months. They are generally easy to apply and provide a noticeable improvement in water repellency.

- Ceramic Coatings for Glass: For longer-lasting and more robust protection, ceramic coatings are an excellent choice. These coatings create a harder, more durable layer that can last for a year or more, offering superior resistance to chemical etching and abrasion.

- Graphene Coatings for Glass: A newer technology, graphene coatings offer advanced hydrophobic properties and exceptional durability, often surpassing traditional ceramic coatings in terms of longevity and performance.

Benefits of Applying a Glass Sealant or Coating

The advantages of applying a sealant or coating to your freshly clay-barred glass are numerous and directly contribute to a better driving experience and easier maintenance. These benefits extend beyond mere aesthetics.Applying a protective layer creates a slick surface that significantly enhances water beading. This means rain will sheet off the glass more effectively, dramatically improving visibility, especially at higher speeds.

This enhanced visibility is a critical safety feature.

“A protected glass surface not only looks better but performs better, contributing to safer driving conditions.”

Beyond improved visibility, these protective layers make cleaning significantly easier. Contaminants like bug splatter, tree sap, and road grime have a harder time adhering to the slick surface, allowing them to be wiped away with minimal effort. This also reduces the risk of scratching the glass during cleaning. Furthermore, protection can help guard against mineral deposits and hard water stains, which can etch into unprotected glass over time.

Future Glass Maintenance Recommendations

Establishing a routine for future glass maintenance will ensure the benefits of clay barring and protection are maximized. This involves regular, gentle cleaning and periodic reapplication of protective treatments.Consistent, proper cleaning is key. When washing your vehicle, use a dedicated glass cleaner and a clean microfiber towel. Avoid using harsh household cleaners or abrasive pads, as these can damage the protective layer and scratch the glass.

- Regular Cleaning: Wash glass with a pH-neutral car wash soap and plenty of water during routine vehicle washes.

- Spot Cleaning: Address bird droppings, bug splatters, and tree sap as soon as possible using a quick detailer spray and a microfiber towel.

- Reapplication of Protection: Monitor the water beading performance. When it diminishes significantly, it’s time to reapply your chosen sealant or coating according to the manufacturer’s instructions. This typically occurs every 6-12 months for sealants and longer for coatings.

- Windshield Wipers: Ensure your windshield wipers are in good condition and replace them when they begin to streak or chatter, as worn wipers can damage protective coatings.

Common Mistakes to Avoid During Glass Clay Barring

Embarking on the journey of glass clay barring can significantly enhance the clarity and smoothness of your vehicle’s windows. However, as with any detailing process, there are common pitfalls that can hinder your success or even cause damage if not approached with care. Understanding these mistakes and how to prevent them is crucial for achieving a flawless finish.This section will guide you through the most frequent errors encountered by those new to glass clay barring, empowering you to navigate the process with confidence and achieve optimal results.

By being aware of these potential issues, you can proactively safeguard your glass and ensure a superior outcome.

Insufficient Lubrication Consequences

Failing to use an adequate amount of lubricant during the clay barring process is a primary cause of surface damage. Lubrication acts as a barrier between the clay bar and the glass, allowing the clay to glide smoothly and pick up contaminants without grinding them into the surface. When lubrication is insufficient, the clay can stick, skip, or even tear, leading to undesirable effects.The consequences of insufficient lubrication are significant and can include:

- Marring and Swirling: Without proper lubrication, the clay bar can drag microscopic abrasive particles across the glass surface, creating fine scratches that appear as swirls or haziness, especially when viewed in direct sunlight.

- Clay Sticking: The clay bar may adhere to the glass, making it difficult to move and increasing the risk of tearing the clay or applying excessive force.

- Reduced Effectiveness: The clay will not effectively encapsulate and remove contaminants, potentially leaving behind embedded particles that can cause long-term issues.

It is imperative to maintain a wet surface at all times. If the lubricant begins to evaporate, reapply it generously before continuing to clay.

Excessive Pressure Risks

Applying too much pressure while claying glass is another common mistake that can lead to damage. The clay bar is designed to lift contaminants through its unique molecular structure, not by brute force. Pressing down too hard can overwhelm the clay’s ability to encapsulate debris and instead force the contaminants into the glass.The risks associated with applying excessive pressure include:

- Deep Scratches: Hard pressure can embed sharp contaminants like grit or sand into the glass, causing deep scratches that may be difficult or impossible to remove without professional polishing.

- Glass Stress Fractures: In extreme cases, significant and uneven pressure could potentially induce micro-fractures in the glass, weakening its structural integrity.

- Clay Degradation: Applying too much force can break down the clay bar prematurely, reducing its effectiveness and potentially leaving residue on the glass.

A gentle, consistent, and even pressure is all that is required for the clay bar to work effectively. Let the clay do the work; your role is to guide it smoothly across the surface.

Preventing Accidental Scratching

Accidental scratching during glass clay barring is often a result of neglecting basic precautions. These scratches are typically caused by contaminants on the glass or the clay itself, or by improper handling of the tools.To prevent accidental scratching, adhere to these essential practices:

- Thorough Washing: Always start with a thoroughly washed and rinsed vehicle. Any loose dirt, dust, or debris left on the glass will be ground into the surface by the clay bar if not removed.

- Regular Clay Folding/Rinsing: As the clay bar picks up contaminants, it becomes saturated. Fold the clay to expose a fresh surface, or rinse it frequently with your chosen lubricant or a separate spray bottle of water. This prevents embedded grit from being dragged across the glass.

- Inspect the Clay: Periodically inspect the clay bar for embedded particles. If you see large or sharp debris, fold or knead the clay to bury it within the bar, or discard it if it is heavily contaminated.

- Use Clean Tools: Ensure that your microfiber towels and applicators are clean and free of any abrasive materials before and during the process.

- Avoid Drop-offs: If you drop the clay bar on the ground, do not use it. Even if it appears clean, it will have picked up abrasive particles that will scratch your glass.

The mantra for preventing scratches is to keep the clay clean, lubricated, and always moving in a controlled manner.

Impact of Using the Wrong Type of Clay Bar

The type of clay bar used can significantly influence the outcome of your glass detailing. While there are many clay bars designed for automotive paint, not all are suitable for glass, and even among those intended for glass, variations exist in their aggressiveness.The impact of using the wrong type of clay bar can be detrimental:

- Paint Clay on Glass: Traditional automotive paint clay bars are often formulated to be more aggressive to remove paint overspray and stubborn contaminants. Using these on glass can be unnecessarily harsh, potentially causing micro-marring or etching if not used with extreme caution and copious lubrication.

- Overly Aggressive Glass Clay: Some glass-specific clay bars are designed for very heavy contamination. Using a highly aggressive bar on lightly soiled glass can lead to over-processing and potential damage.

- Low-Quality Clay: Inexpensive or low-quality clay bars may have inconsistent textures or contain impurities that can lead to scratching, even with proper technique.

For glass detailing, it is best to opt for a clay bar specifically designed for automotive glass. These are typically formulated to be gentler while still effective at removing bonded contaminants like water spots, tree sap, and road film. If you are unsure, start with a medium-grade glass clay bar, as it offers a good balance of effectiveness and safety for most situations.

Advanced Techniques and Considerations for Glass Clay Barring

Moving beyond the basic application, several advanced techniques and considerations can elevate your glass clay barring results and ensure you can tackle various surfaces and situations with confidence. Understanding these nuances will allow for a more comprehensive and effective detailing process.

Exterior and Interior Glass Claying

The process for claying exterior and interior glass surfaces shares many similarities, but distinct approaches are necessary due to environmental exposure and different types of contaminants. Exterior glass is exposed to road grime, industrial fallout, water spots, and tree sap, requiring a robust cleaning approach. Interior glass, while less exposed to harsh elements, can accumulate dust, film from interior plastics, and residue from vaping or smoking, necessitating a gentler touch and different cleaning agents.When claying the exterior, a liberal amount of lubricant is crucial to prevent marring and ensure the clay glides smoothly over the surface.

For interior glass, a dedicated interior glass cleaner can often serve as an effective lubricant, minimizing the risk of transferring odors or residues from exterior detailing products. It’s also important to work in smaller sections on the interior, as visibility can be more challenging, and overspray from lubricants needs to be managed carefully to avoid smudging other interior surfaces.

Claying Specialized Glass Surfaces

Specialized glass surfaces, such as panoramic sunroofs, require particular attention due to their size, curvature, and often their tinted or coated nature. Panoramic roofs present a larger canvas, meaning you might need more lubricant and potentially more time to cover the entire area effectively. The curvature can also mean that certain areas are harder to reach, requiring careful maneuvering of the clay bar and lubricant applicator.For tinted or coated glass, it is paramount to use a clay bar of the appropriate grade.

Coarser grades can potentially damage delicate tint films or anti-reflective coatings, leading to permanent marring or hazing. Always test a small, inconspicuous area first if you are unsure about the compatibility of the clay bar and lubricant with the specific coating. The lubricant used should also be pH-neutral and free from harsh solvents that could degrade tint or coatings.

Clay Bar Grades for Glass

The selection of clay bar grades is critical for effective and safe glass detailing. Similar to paint claying, glass clay bars come in varying levels of aggressiveness, often categorized as fine, medium, and heavy cut.

- Fine Grade Clay: This is the most commonly used grade for glass and is ideal for removing light surface contaminants such as dust, light water spots, and minor road film. It offers the lowest risk of marring and is suitable for regular maintenance detailing.

- Medium Grade Clay: This grade is more aggressive and is used for tackling moderate contaminants like stubborn water spots, light overspray paint, and more ingrained road grime. It requires more lubricant and careful inspection of the glass surface after use.

- Heavy Cut Clay: Reserved for the most severe contamination, such as heavy industrial fallout, rail dust, or dried bug splatter that has bonded strongly to the glass. This grade should be used with extreme caution, ample lubrication, and always followed by a finer grade clay to remove any micro-marring. It is generally recommended to avoid heavy cut clays on tinted or coated glass unless absolutely necessary and after thorough testing.

Clay Bar Storage and Maintenance

Proper storage and maintenance of your clay bar are essential for its longevity and effectiveness, as well as for preventing contamination of your vehicle’s surfaces. A contaminated clay bar can introduce new scratches and swirls.

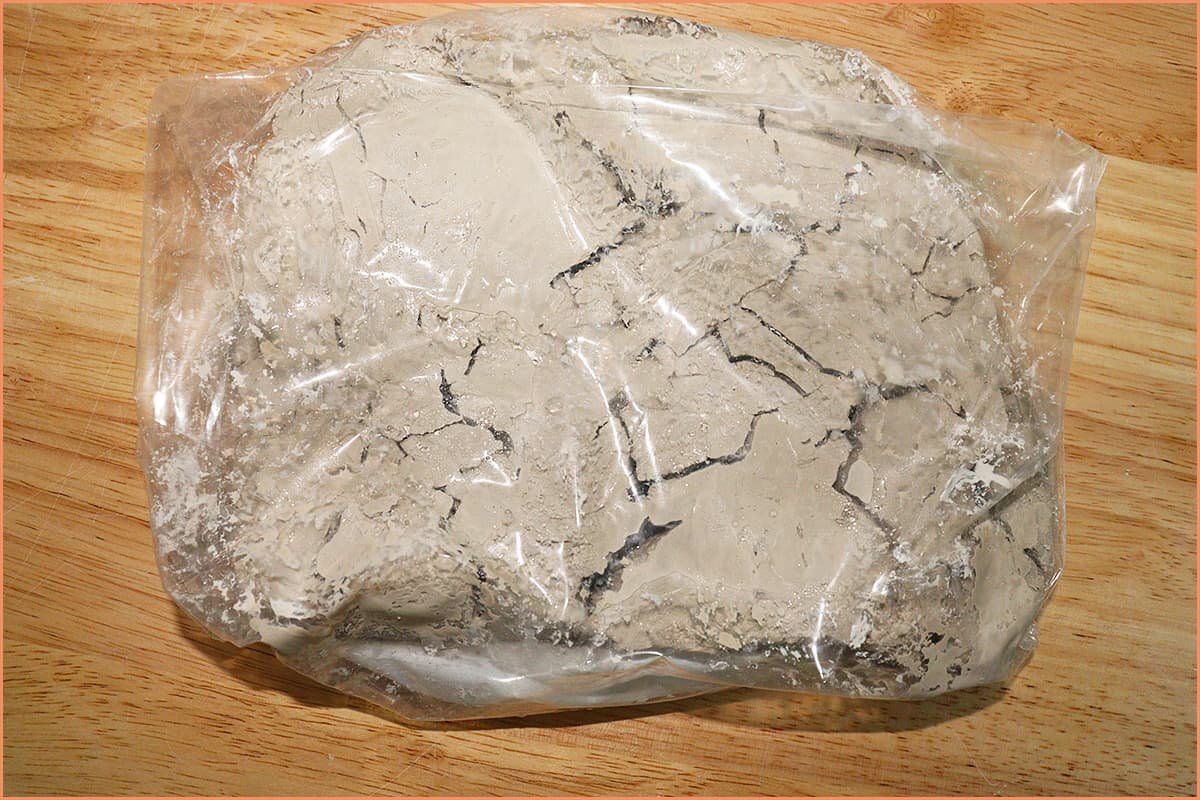

Always store your clay bar in its original container or a sealed plastic bag to prevent it from picking up dust and debris.

Before and after each use, inspect the clay bar for any embedded particles like grit or dirt. If visible contaminants are present, carefully knead the clay to bury them within the bar. If the clay becomes excessively dirty or dropped on the ground, it is best to discard it, as embedded grit can cause significant damage to glass. Reusable clay bars can be gently cleaned with a clay lubricant or mild soap and water, then allowed to air dry completely before storage.

Manual Claying Versus Clay Mitt

Both manual claying with a traditional clay bar and using a clay mitt offer effective ways to decontaminate glass, but they differ in application and suitability for certain tasks.

| Feature | Manual Clay Bar | Clay Mitt |

|---|---|---|

| Application Method | Requires direct manipulation of the clay bar, often folded or flattened, with lubricant applied liberally to the surface. | A mitt or pad infused with clay material, which is slipped over the hand or a buffer pad. Lubricant is applied to the glass or the mitt. |

| Control and Precision | Offers high precision for intricate areas and detailed work. Allows for tactile feedback, enabling the user to feel contaminants. | Faster coverage over larger, flatter areas. Can be less precise in tight corners or complex curves. |

| Speed of Work | Generally slower, especially for large surfaces, but allows for more detailed inspection. | Significantly faster for large surface areas like windshields and panoramic roofs. |

| Contaminant Handling | Contaminants are embedded into the clay, which can be kneaded out. Risk of scratching if not properly maintained. | Contaminants are lifted and held within the clay matrix. Some mitts have a rinsing mechanism or require frequent washing. |

| Best Use Cases | Detailed work, smaller glass panels, when maximum tactile feedback is desired, and for very delicate or coated glass. | Large glass surfaces, quick decontamination, and for users who prefer a less hands-on approach. |

Last Recap

In conclusion, by mastering the art of clay barring your car’s glass, you unlock a new level of clarity and protection, ensuring a safer and more visually appealing driving experience. This detailed process, from preparation to post-care, transforms ordinary glass into a gleaming, smooth surface, ready to face the elements. Embrace these techniques for a finish that truly shines, enhancing both the aesthetics and integrity of your vehicle.