Embarking on the journey of paint correction can seem daunting, but with the right guidance, achieving a showroom-quality finish is well within reach. How to Use a Dual Action Polisher for the First Time is your essential companion, demystifying this powerful tool and empowering you to transform your vehicle’s appearance. This comprehensive guide will walk you through every step, from understanding the fundamental principles to mastering advanced techniques, ensuring a rewarding and successful experience.

We will delve into the core concepts of dual action polishing, exploring its benefits over traditional methods and what a beginner can realistically expect. A detailed checklist of essential tools and supplies will ensure you’re fully prepared, followed by a crucial section on safety to protect both yourself and your vehicle. Understanding the components of your polisher, selecting the right pads and compounds, and meticulously preparing your car’s surface are all covered in detail.

Finally, we will guide you through the actual polishing technique, address various paint conditions, and discuss finishing and protection, all while offering insights into common mistakes and how to avoid them.

Introduction to Dual Action Polishers

Welcome to the exciting world of paint correction and enhancement! If you’ve ever admired a car with a mirror-like finish, chances are a dual action polisher played a key role in achieving that brilliance. This guide is designed to demystify this powerful tool and equip you with the knowledge to use it confidently for the first time.At its core, a dual action (DA) polisher is an electric tool that oscillates and rotates simultaneously.

This unique movement is crucial because it mimics the natural motion of a human hand waxing a car, but with far greater speed and consistency. Unlike rotary polishers, which spin in a single, forceful direction, the DA polisher’s random orbit prevents excessive heat buildup and significantly reduces the risk of burning through paint or creating holograms, making it the ideal choice for beginners.

The Fundamental Concept of a Dual Action Polisher

A dual action polisher operates on a principle of controlled, random movement. The pad attached to the polisher spins on a spindle, while that spindle is also mounted on an offset cam. This offset mechanism causes the pad to move in an elliptical, random orbit, similar to how you might move your hand in small circles when applying wax. This random pattern ensures that the polishing or compounding process is spread evenly across the surface, minimizing the chance of localized heat damage or paint marring.

Primary Benefits of Using a Dual Action Polisher

The advantages of employing a dual action polisher are numerous, especially when compared to older, more demanding methods of paint correction. The user-friendly nature of the DA polisher makes it accessible to enthusiasts of all skill levels.

- Safety: The random orbital action significantly reduces the risk of inflicting damage to the paintwork, such as burning through clear coat or creating swirl marks (holograms). This makes it an exceptionally forgiving tool for those new to machine polishing.

- Ease of Use: The tool is designed to be intuitive. The random orbit allows for more freedom of movement and less precision required from the user to avoid damage, unlike a rotary polisher which demands strict technique.

- Efficiency: DA polishers can effectively remove light to moderate paint defects like swirl marks, light scratches, oxidation, and water spots much faster than manual methods.

- Versatility: With different pads and compounds, a DA polisher can be used for a wide range of tasks, from aggressive paint correction to light polishing and applying waxes or sealants.

Beginner Expectations When First Using a Dual Action Polisher

When you first pick up a dual action polisher, the experience can be both exciting and a little intimidating. However, with a little preparation and understanding, you’ll quickly gain confidence. You can expect to feel a slight vibration as the tool works, which is normal. The key is to let the machine do the work; applying excessive pressure is a common beginner mistake and can lead to less effective results and potential paint damage.The initial results you’ll see will be a noticeable improvement in the clarity and gloss of your vehicle’s paint.

Light scratches and swirl marks will begin to disappear, and the surface will feel much smoother. It’s important to remember that paint correction is a process, and with practice, you’ll learn to tackle more significant defects. Patience and a methodical approach are your greatest allies when starting out.

Essential Tools and Supplies Checklist

Embarking on your dual-action polishing journey requires a well-prepared arsenal. Having the right tools and supplies not only ensures a smoother and more effective polishing process but also contributes significantly to achieving professional-grade results and protecting your vehicle’s paintwork. This checklist is designed to guide first-time users through gathering everything they need for a successful detailing session.A comprehensive understanding of each item’s purpose will empower you to make informed decisions and utilize your equipment to its fullest potential.

We have categorized these essentials to provide a clear and organized approach to your preparation.

Safety Gear

Prioritizing safety is paramount when working with automotive detailing equipment. Protective gear ensures your well-being throughout the polishing process, preventing potential harm from dust, chemicals, or mechanical operation.

- Safety Glasses: Essential for protecting your eyes from polishing dust, stray compounds, and accidental splashes of cleaning solutions.

- Gloves: Nitrile or latex gloves protect your skin from chemicals in polishes and compounds, and also provide a better grip on your tools.

- Face Mask or Respirator: Crucial for preventing inhalation of fine paint particles and chemical fumes, especially when working with aggressive compounds or in poorly ventilated areas.

- Ear Protection: Dual-action polishers can generate significant noise, and earplugs or earmuffs are recommended for prolonged use to prevent hearing damage.

Dual Action Polisher and Accessories

The heart of the operation is the dual-action polisher itself, along with its essential companions. Understanding the function of each component will ensure you select the right tools for the job and use them effectively.

- Dual Action (DA) Polisher: The primary tool for paint correction and refinement. DA polishers offer a safer and more user-friendly experience compared to rotary polishers, as their random orbital action significantly reduces the risk of paint damage.

- Polishing Pads: These are crucial for applying compounds and polishes. They come in various densities and materials (foam, microfiber, wool) for different tasks, from aggressive cutting to delicate finishing. For a first-time user, a set with a light, medium, and finishing pad is ideal.

- Backing Plate: This attaches to the polisher and provides a surface to which the polishing pads adhere, typically via hook-and-loop fastening. Ensure the backing plate size is compatible with your polisher and the pads you intend to use.

- Extension Cord: A heavy-duty, outdoor-rated extension cord is necessary if your polisher is corded and your workspace is not near a power outlet. Ensure it’s long enough to allow freedom of movement without strain.

Polishing and Finishing Products

The chemical agents used in conjunction with your polisher are what actually perform the paint correction and enhancement. Selecting the appropriate products for your paint’s condition is key to achieving the desired outcome.

- Compound: A more abrasive product used to remove deeper scratches, oxidation, and swirl marks. Start with a less aggressive compound if unsure.

- Polish: A less abrasive product used to refine the paint after compounding, further removing minor imperfections and enhancing gloss.

- Finishing Polish/Glaze: Used as the final step to maximize gloss and create a deep, rich shine. Glazes often contain fillers that temporarily hide minor imperfections.

- Paint Cleaner/Pre-wax Cleaner: Applied before wax or sealant to remove any remaining oils or residue from the polishing process, ensuring optimal bonding of the protective layer.

- IPA (Isopropyl Alcohol) Solution or Panel Wipe: A diluted solution (typically 15-50% IPA in distilled water) used to wipe down the paint surface between steps to remove polishing oils and reveal true paint condition, ensuring proper product performance.

Applicators and Wiping Materials

These items are essential for applying products and safely removing them without introducing new scratches. Their quality and cleanliness directly impact the final finish.

- Microfiber Towels: A large quantity of high-quality, plush microfiber towels is indispensable. Use different towels for different purposes: one for applying IPA, another for buffing off compounds/polishes, and a separate set for final wipe-downs.

- Applicator Pads (for initial product application): While pads on the polisher apply the product, sometimes it’s beneficial to pre-load the pad with a small amount of product using a separate applicator, especially for the initial application.

- Detailing Brushes: Small brushes can be useful for cleaning edges, emblems, and tight crevices where polishing pads cannot reach, ensuring a thorough job.

Surface Preparation and Protection

Proper preparation of the surface and subsequent protection are critical steps that complement the polishing process and ensure longevity of the results.

- Car Wash Soap and Wash Mitt: Thoroughly washing and drying the vehicle before polishing is essential to remove loose dirt and debris that could cause scratches during the polishing process.

- Clay Bar and Lubricant: A clay bar kit is used to decontaminate the paint surface, removing embedded contaminants like industrial fallout, tar, and overspray that washing alone cannot remove. This is a crucial step before polishing.

- Wax or Sealant: After polishing, applying a protective layer of wax or sealant shields the paint from environmental damage, UV rays, and contaminants, while also enhancing the shine.

- Drying Towels: Large, highly absorbent microfiber drying towels are needed to safely dry the vehicle after washing, minimizing water spots.

Organization and Workspace

A well-organized workspace enhances efficiency and safety, making the entire detailing process more enjoyable and less prone to errors.

- Tool Bag or Cart: To keep all your tools and supplies organized, easily accessible, and protected.

- Bucket(s) with Grit Guards: For washing the vehicle. Using two buckets (one for soapy water, one for rinsing the wash mitt) with grit guards at the bottom significantly reduces the risk of reintroducing dirt to the paint.

- Spray Bottles: For holding your IPA solution, water, or other detailing sprays.

- Masking Tape: High-quality automotive masking tape is essential for protecting trim, rubber seals, and plastic parts from polishing compounds and pads. This prevents staining and damage.

Safety First: Protecting Yourself and Your Vehicle

Operating a dual-action polisher is an exciting step towards achieving a flawless finish on your vehicle, but it’s paramount to prioritize safety throughout the process. Adhering to proper safety protocols not only protects you from potential harm but also safeguards your vehicle’s paintwork from accidental damage.This section will guide you through the essential safety measures, including the appropriate use of personal protective equipment (PPE) and understanding potential hazards to ensure a smooth and secure polishing experience.

Personal Protective Equipment (PPE)

Wearing the correct personal protective equipment is the first line of defense against common workshop hazards. This equipment is designed to shield you from airborne particles, chemical exposure, and physical discomfort, allowing you to focus on the task at hand with confidence.To ensure your safety, it is crucial to utilize the following PPE:

- Safety Glasses or Goggles: Essential for protecting your eyes from polishing dust, debris, and accidental splashes of polishing compounds or solvents. Ensure they fit snugly to prevent particles from entering.

- Gloves: Nitrile or latex gloves protect your skin from the chemicals in polishing compounds and prevent oils from your hands from contaminating the paint surface.

- Face Mask or Respirator: A dust mask (N95 or higher) is recommended to prevent inhalation of fine paint particles and polishing residue, especially in poorly ventilated areas.

- Ear Protection: While not always strictly necessary for short polishing sessions, earplugs or earmuffs can be beneficial if you plan on extended use or if your polisher is particularly loud.

- Comfortable, Non-Restrictive Clothing: Wear clothing that allows for freedom of movement and is unlikely to get caught in the polisher. Avoid loose sleeves or dangling jewelry.

Potential Hazards and Mitigation Strategies

Understanding the potential risks associated with using a dual-action polisher is key to preventing accidents and ensuring a positive outcome. By being aware of these hazards and implementing the following mitigation strategies, you can significantly reduce the likelihood of encountering problems.Potential hazards and their corresponding mitigation strategies include:

| Hazard | Mitigation Strategy |

|---|---|

| Paint Damage: Overheating the paint, creating buffer trails, or uneven polishing can lead to permanent damage. | Maintain a consistent, light to moderate pressure. Keep the polisher moving at all times, avoiding dwelling on one spot. Use the correct pad and compound for the paint’s condition. Work in small, manageable sections. |

| Dust and Debris Inhalation: Polishing creates fine dust that can be harmful if inhaled. | Always wear a suitable face mask or respirator. Ensure the work area is well-ventilated. Wipe down surfaces frequently to reduce airborne particles. |

| Eye Irritation: Flying debris or compound can get into your eyes. | Wear safety glasses or goggles at all times during operation. |

| Electrical Hazards: Damaged cords or improper use near water can pose an electrical risk. | Inspect the power cord for any damage before each use. Avoid using the polisher in wet conditions or near water sources. Ensure your electrical outlet is properly grounded. |

| Polisher Malfunction: Overheating the machine or improper maintenance can lead to failure. | Follow the manufacturer’s instructions for operation and maintenance. Allow the polisher to cool down periodically during extended use. Do not force the machine beyond its intended capacity. |

| Ergonomic Strain: Prolonged use can lead to fatigue and strain on your body. | Take regular breaks. Adjust your posture to minimize strain. Utilize the polisher’s handle effectively for better control and support. |

Pre-Operation Safety Checks

Before you even connect your dual-action polisher to power, a thorough pre-operation check is essential. This proactive step helps identify any potential issues that could lead to accidents or damage, ensuring that both you and your vehicle are protected.Perform the following checks before commencing any polishing work:

- Inspect the Polisher: Check the power cord for any cuts, frays, or damage. Ensure the backing plate is securely attached and free from defects. Verify that the ventilation ports are clear of debris.

- Examine the Pads: Ensure the polishing pads are clean, free from hardened compound, and not excessively worn or torn. A damaged pad can lead to uneven results and potential paint damage.

- Assess the Work Area: Ensure the area is clean, well-lit, and free from tripping hazards. Remove any unnecessary items from the vicinity of the vehicle. If working outdoors, ensure stable ground.

- Confirm Ventilation: If working in a garage, open doors and windows to ensure adequate airflow. Good ventilation helps dissipate dust and any fumes from polishing compounds.

Understanding Your Dual Action Polisher

Before you begin polishing your vehicle, it’s crucial to familiarize yourself with the tool itself. A dual action (DA) polisher, also known as an orbital polisher, is designed to be user-friendly and significantly reduce the risk of paint damage compared to rotary polishers. Understanding its components and how they function will empower you to use it effectively and safely.This section will guide you through the essential parts of your DA polisher, explaining their roles in the polishing process and helping you gain confidence in operating your new tool.

Key Components of a Dual Action Polisher

A typical dual action polisher is a relatively simple yet effective machine. Recognizing these parts will help you understand how it operates and how to maintain it.

- Head/Motor Housing: This is the main body of the polisher, containing the electric motor that drives the polishing action. It’s where you’ll typically find the power switch and sometimes speed controls.

- Spindle/Shaft: Emerging from the head, this rotating shaft connects the motor to the backing plate.

- Handle(s): Most DA polishers come with at least one auxiliary handle, often a D-handle or a loop handle. These provide leverage and control during operation, allowing for a stable grip and even pressure distribution.

- Power Cord: This supplies electricity to the motor. Ensure it’s long enough to reach your work area without tension or the need for extensions that might compromise power delivery.

- Ventilation Grilles: These are crucial for preventing the motor from overheating. Always ensure these are unobstructed during operation.

Variable Speed Control Function

The variable speed control is one of the most important features of a dual action polisher, offering precise control over the machine’s rotation and oscillation. This allows you to adapt the polishing intensity to the specific task and paint condition.

The variable speed dial allows for a gradual increase in rotational speed, minimizing the risk of paint damage and ensuring effective product application.

Typically, DA polishers have a dial or buttons that allow you to select a speed range. Lower speeds are generally used for applying polishes, waxes, or sealants, while higher speeds are employed for cutting or compounding, depending on the aggressiveness of the pad and product combination. Starting at a lower speed and gradually increasing it as needed is a fundamental principle for safe and effective polishing.

For instance, when applying a finishing polish, you might start at speed 2 or 3 and work your way up to speed 4 or 5, whereas a heavy cut compound might require starting at speed 4 and progressing to speed 6.

Backing Plates and Their Uses

The backing plate is the component that attaches to the polisher’s spindle and serves as the base for your polishing pads. The size and type of backing plate significantly influence the polisher’s performance and its suitability for different areas of the vehicle.Here’s a breakdown of common backing plate types and their applications:

- 5-inch Backing Plate: This is a versatile size, suitable for most general body panels such as doors, fenders, hoods, and roofs. It provides a good balance between coverage and maneuverability, making it ideal for a wide range of polishing tasks.

- 3-inch Backing Plate: Smaller backing plates are designed for working on more intricate areas. These are excellent for polishing bumpers, pillars, door jambs, spoilers, and other tight or contoured sections of the vehicle where a larger plate would be difficult to control and could risk contacting adjacent surfaces.

- 6-inch Backing Plate: While less common on DA polishers compared to 5-inch, some larger machines may come with or accept 6-inch plates. These are generally for very large, flat surfaces like the roof or hood of an SUV or truck, offering faster coverage but requiring more careful handling due to their size.

The material of the backing plate also matters; polyurethane is common as it offers a good balance of flexibility and rigidity, helping to absorb some vibration and conform to curves. Some backing plates feature hook-and-loop (Velcro) fasteners to securely attach polishing pads, while others might use a bolt-on system. For most users, hook-and-loop backing plates are preferred for their ease of pad changes.

Selecting the Right Pads and Compounds

Choosing the correct polishing pads and compounds is paramount to achieving the desired paint correction results with your dual action polisher. The interplay between the pad’s aggressiveness and the compound’s cutting power dictates how effectively you can remove defects and how refined the finish will be. Understanding these components will empower you to tackle various paint conditions with confidence.The world of polishing pads and compounds is designed to offer a spectrum of abrasiveness, allowing detailers to tailor their approach to specific paint imperfections.

From heavy defect removal to the final gloss enhancement, each element plays a crucial role in the paint correction process.

Polishing Pad Types and Abrasiveness

Polishing pads are typically made from foam, wool, or microfiber, each offering different levels of cutting and finishing capabilities. The density and cell structure of foam pads, the material of wool pads, and the weave of microfiber pads all contribute to their effectiveness. Generally, denser pads with more aggressive materials will cut more, while softer, more open-celled pads will finish finer.

- Cutting Pads: These are the most aggressive pads, designed to remove significant paint defects such as deep scratches, heavy oxidation, and severe swirl marks. They are often made from dense foam, wool, or a coarse microfiber. They remove more paint material, so careful technique is essential to avoid damaging the clear coat.

- Polishing Pads: These pads strike a balance between cutting and finishing. They are ideal for removing moderate defects like light to medium swirls, water spots, and light oxidation. They are typically made from medium-density foam or a finer grade of microfiber.

- Finishing Pads: These are the least aggressive pads, designed to refine the paintwork after compounding or polishing and to apply waxes and sealants. They are usually made from very soft, open-celled foam or a very fine microfiber. Their primary role is to enhance gloss and clarity without removing significant amounts of paint.

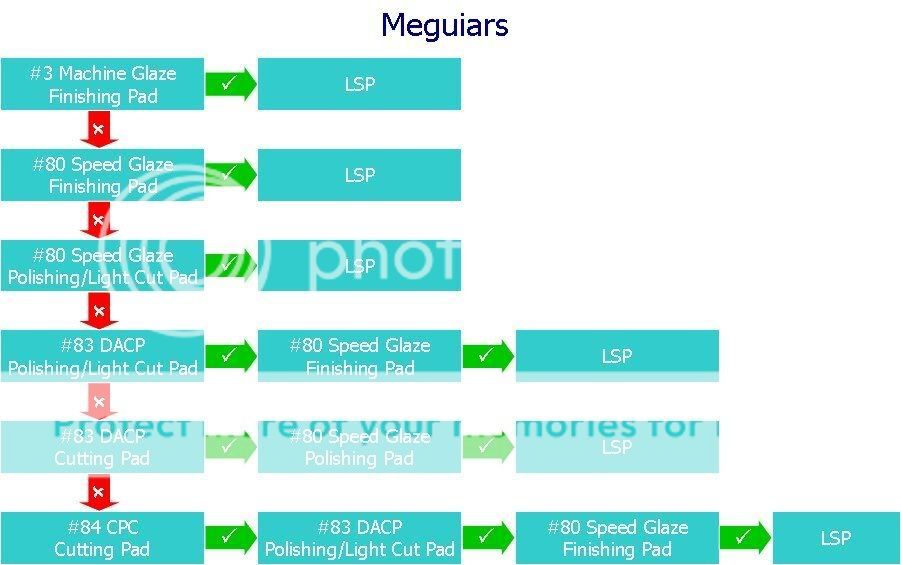

Matching Pads to Compounds

The effectiveness of a polishing pad is significantly amplified when paired with the correct compound or polish. A compound is generally more abrasive and used for heavier defect removal, while a polish is less abrasive and used for lighter correction and finishing. The combination of pad and product must be carefully considered to achieve optimal results without causing unintended damage.A common rule of thumb is to pair more aggressive pads with more aggressive compounds and less aggressive pads with less aggressive polishes.

However, it’s also possible to use a less aggressive pad with a more aggressive compound to control the cutting action or a more aggressive pad with a lighter polish for a more refined cut.

| Pad Type | Compound/Polish Type | Typical Use | Example Products |

|---|---|---|---|

| Cutting Pad (Wool/Coarse Microfiber/Dense Foam) | Heavy Cut Compound | Deep scratches, heavy oxidation, severe swirls | Menzerna Heavy Cut 400, Meguiar’s Ultimate Compound |

| Polishing Pad (Medium Foam/Fine Microfiber) | Medium Cut Polish/All-in-One Polish | Moderate swirls, water spots, light oxidation | Meguiar’s M205 Ultra Finishing Polish, Griot’s Garage Correcting Cream |

| Finishing Pad (Soft Foam/Very Fine Microfiber) | Fine Polish/Finishing Polish/Glaze | Enhance gloss, remove light haze, apply protection | Sonax Perfect Finish, Chemical Guys VSS (V-S-S) |

Choosing the Right Compound or Polish

Selecting the appropriate compound or polish depends on the condition of your vehicle’s paint. It’s always advisable to start with the least aggressive combination of pad and product and step up only if necessary. Testing in an inconspicuous area is a highly recommended practice to determine the most effective solution for your specific paint.

- For heavy defects: If your paint has deep scratches, significant oxidation, or widespread, deep swirl marks, you will need a heavy-cut compound paired with a cutting pad. These products contain larger abrasive particles that effectively level the paint surface.

- For moderate defects: For more common issues like light to medium swirls, minor water spots, or dullness, a medium-cut polish or an all-in-one polish used with a polishing pad will be sufficient. These have finer abrasives that remove less material but are effective for these levels of defects.

- For light correction and gloss enhancement: If your paint is relatively free of defects but could benefit from enhanced gloss and clarity, or if you are applying a sealant or wax, a finishing polish or glaze used with a finishing pad is the ideal choice. These products contain very fine abrasives or fillers to create a slick, high-gloss finish.

The principle of “least aggressive first” is crucial in paint correction. Always start with the mildest product and pad combination that can effectively address the paint defect. This approach minimizes unnecessary paint removal and reduces the risk of creating new imperfections.

Preparing the Vehicle for Polishing

Before you can begin the satisfying process of polishing your vehicle with a dual-action polisher, meticulous preparation is paramount. This initial stage ensures that you are working on a clean canvas, free from contaminants that could scratch the paint or hinder the effectiveness of your polishing compounds. A thorough preparation routine not only protects your vehicle’s finish but also maximizes the results you achieve.The preparation process involves a series of steps designed to remove all surface impurities and identify areas requiring specific attention.

This careful groundwork lays the foundation for a flawless polish and a stunning, protected finish.

Vehicle Washing

A clean surface is the absolute prerequisite for effective polishing. Any dirt, grit, or debris left on the paint can be ground into the clear coat by the polisher and pads, leading to new scratches and swirls. Therefore, a comprehensive wash is essential.

- Two-Bucket Wash Method: This is the industry standard for safe washing. Use one bucket filled with soapy water and another with clean rinse water. Dip your wash mitt into the soap bucket, wash a section of the vehicle, then rinse the mitt thoroughly in the clean water bucket before returning it to the soap bucket. This prevents transferring dirt back onto the paint.

- High-Quality Car Shampoo: Employ a pH-neutral car shampoo specifically designed for automotive paint. Avoid household detergents, as they can strip protective waxes and sealants and be too harsh for clear coats.

- Gentle Wash Mitt: Opt for a plush microfiber or lambswool wash mitt. These materials are soft and effectively lift dirt away from the paint surface without causing micro-scratches.

- Work from Top to Bottom: Begin washing the roof and work your way down the vehicle. This ensures that dirt and grime from higher surfaces don’t run down onto already cleaned lower sections.

- Rinse Thoroughly: After washing each section, rinse it immediately to prevent the soap from drying on the paint, which can leave water spots.

Surface Decontamination

Even after a thorough wash, microscopic contaminants can remain embedded in the paint. These include industrial fallout, tar, tree sap, and iron particles. Decontamination removes these stubborn impurities, creating a truly smooth surface for polishing.The process of decontamination typically involves two key stages: chemical decontamination and mechanical decontamination.

Chemical Decontamination

This step utilizes specialized chemical cleaners to break down and dissolve bonded contaminants.

- Iron Remover: Apply an iron remover spray to the vehicle’s surface. This product reacts with iron particles (like brake dust) and turns a purple or red color as it dissolves them. Allow it to dwell for the manufacturer’s recommended time, then rinse thoroughly.

- Tar and Bug Remover: For stubborn tar spots and bug residue, use a dedicated tar and bug remover. Apply it to the affected areas, let it soak for a moment, and then gently wipe away with a microfiber towel.

- All-Purpose Cleaner (APC) or Panel Wipe: After the specialized chemical treatments, a diluted APC or a dedicated panel wipe can be used to ensure all chemical residues are removed and the surface is prepped for the next step.

Mechanical Decontamination (Clay Bar or Clay Mitt)

Once chemical decontamination has loosened contaminants, mechanical methods physically lift them off the paint.

- Clay Bar/Mitt: A clay bar or clay mitt is used with a lubricant (usually a quick detailer spray or a dedicated clay lubricant). Work in small sections, gently gliding the clay over the paint. You will feel it drag initially, but as it cleans the surface, it will glide smoothly. Fold or knead the clay frequently to expose a fresh surface and prevent dragging contaminants across the paint.

Masking Off Trim and Sensitive Areas

Masking is a critical step that protects non-paint surfaces from the abrasive action of the polisher and compounds. It also prevents polish from getting into crevices, which can be difficult to remove later.

- Materials: Use automotive-grade painter’s tape, typically 1-inch or 1.5-inch width. For more delicate areas, consider using a fine-line tape.

- Areas to Mask:

- All unpainted plastic and rubber trim (e.g., window surrounds, bumper trim, door handles, emblems).

- Headlights, taillights, and fog lights (unless you intend to polish them).

- Panel gaps where paint meets trim or glass.

- Door jambs and edges of doors.

- Convertible tops or any fabric/vinyl surfaces.

- Technique: Apply the tape neatly and firmly, ensuring good adhesion. For trim, it’s often best to tape just along the edge where the trim meets the paint. For panel gaps, ensure the tape is flush with the edge of the paint.

Paint Inspection for Imperfections

With the vehicle clean and decontaminated, it’s time to thoroughly inspect the paint for imperfections that will be addressed during the polishing process. This inspection helps you determine the severity of the paint defects and choose the appropriate pads and compounds.

- Lighting is Key: Use a high-quality inspection light, such as an LED detailing light or a powerful flashlight. Move the light across the surface at different angles to reveal swirls, scratches, oxidation, and other defects. Natural daylight on a cloudy day is also excellent for inspection.

- Common Imperfections:

- Swirl Marks: These are fine, concentric scratches that appear as spiderwebs on the paint surface, usually caused by improper washing or drying techniques.

- Scratches: These can range from light wash-induced scratches to deeper clear coat scratches.

- Oxidation: This is a dulling or chalky appearance of the paint, often seen on older vehicles or those exposed to harsh sunlight.

- Water Spots: Mineral deposits left behind after water evaporates.

- Bird Dropping Etching: Acidic bird droppings can etch into the clear coat.

- Severity Assessment:

- Light Defects: Swirls and very light scratches can often be removed with a mild compound and a finishing pad.

- Moderate Defects: Deeper scratches and moderate oxidation may require a more aggressive compound and a cutting pad.

- Deep Defects: Very deep scratches that you can feel with your fingernail are typically beyond the scope of machine polishing and may require repainting.

By following these meticulous preparation steps, you ensure your dual-action polisher has the best possible environment to work in, leading to a superior and more durable finish.

Mastering the Polishing Technique

Embarking on your first dual-action polishing adventure can seem daunting, but with a systematic approach and the right technique, you’ll achieve impressive results. This section breaks down the core polishing process into manageable steps, ensuring you gain confidence and proficiency with every pass. Remember, patience and precision are key to unlocking your vehicle’s true shine.Understanding the fundamental movements and product application is crucial for effective paint correction.

This guide will walk you through the entire process, from applying polish to your pad to knowing when a section is perfectly refined.

Applying Polish to the Pad

Properly loading your polishing pad with compound is essential for even application and to prevent dry spots that can lead to marring. Too little polish will result in the pad skipping and not cutting effectively, while too much can create a mess and waste product.

Here’s the recommended method for applying polish:

- Start with a clean and primed pad. If it’s a new pad, it should be lightly misted with a detail spray or the polish itself to create a slick surface.

- Dispense several pea-sized dots of polish onto the pad. The number of dots can vary depending on the pad size and the polish viscosity, but typically 3-5 dots are sufficient for a 2×2 foot working area.

- Distribute these dots evenly across the surface of the pad, avoiding the very center where the backing plate attaches.

Working the Polish Across the Paint Surface

The way you move the polisher across the paint is as important as the polish itself. A consistent and controlled motion ensures the polish is worked evenly, allowing it to break down and perform its corrective action without creating new defects.

Follow these steps for effective polishing:

- Placement: Gently place the polisher, with the pad flat against the paint surface, in the center of your intended working area.

- Start Slow: Begin with the polisher turned off or at its lowest speed setting. This prevents polish from slinging off the pad upon startup.

- Engage Speed: Once the pad is flat on the paint, engage the polisher and slowly increase the speed to your working setting (typically 3-4 for most compounds).

- Controlled Passes: Move the polisher in slow, deliberate passes, overlapping each pass by about 50%. Work in a cross-hatch pattern – first horizontally, then vertically.

- Consistent Pressure: Apply light to moderate, consistent pressure. You should feel the polisher working, but you’re not trying to force it. Let the machine and the polish do the work.

- Work the Area: Continue with your cross-hatch passes until the polish appears to have thinned out and become almost clear. This indicates the polish has been worked sufficiently.

- Wipe Away Residue: Immediately after completing a section, use a clean microfiber towel to gently wipe away any polish residue. Inspect the area for clarity and any remaining product.

“The key to a successful polish is slow, overlapping passes with consistent pressure, allowing the product to do its job effectively.”

Pad Cleaning and Maintenance During the Process

Keeping your polishing pads clean and in good condition throughout the polishing process is vital for optimal performance and to prevent the transfer of contaminants back onto the paint. A dirty pad can clog up, reduce its effectiveness, and even cause new scratches.

Implement these practices for effective pad maintenance:

- Initial Cleaning: Before starting, ensure your pads are clean and free of any debris.

- Frequent Brushing: Periodically use a dedicated pad brush to remove excess compound and dust from the pad face. Do this every few panels or as needed.

- Pad Washer (Optional): For more intensive detailing, a pad washer can be a valuable tool to thoroughly clean pads between uses.

- Inspection: Regularly inspect your pads for signs of wear, tears, or excessive buildup. Replace pads as they become worn out.

Identifying When a Section is Sufficiently Polished

Determining when to stop polishing a particular section is a skill that develops with practice. The visual cues are your primary guide. The polish will change in appearance as it’s worked, and the paint’s clarity will significantly improve.

Look for these indicators:

- Product Breakdown: The polish will transform from a opaque, creamy substance to a thin, almost transparent film. This signifies that the abrasives have done their work.

- Increased Clarity: The paint surface will begin to look noticeably clearer and more reflective. Swirl marks and light scratches will start to disappear.

- Smoothness: The surface will feel smoother to the touch after the polish has been worked and wiped off.

- Lack of Drag: The polisher will glide more easily across the paint as the polish breaks down. If you feel significant drag, you may need to add a touch more polish or work the existing product a bit longer.

Working with Different Paint Conditions

Understanding how to adapt your dual-action polisher technique to various paint conditions is crucial for achieving optimal results. Not all paint defects are the same, and a one-size-fits-all approach can be ineffective or even detrimental. This section will guide you through addressing common paint imperfections, from minor blemishes to more significant issues, ensuring you use the right tools and techniques for each scenario.

Light Swirl Marks and Scratches

Light swirl marks, often visible as spiderweb-like patterns in direct sunlight, and minor surface scratches are among the most common paint imperfections. These are typically superficial and can be effectively removed with a mild polishing approach. The goal here is to gently abrade the clear coat just enough to level the surface without removing excessive material.To address light swirl marks and scratches, you will generally use a less aggressive combination of pad and polish.

A fine-cut polish paired with a finishing or polishing pad is usually sufficient. The process involves applying a small amount of polish to the pad, spreading it evenly over a small section of the paint, and then working it in with the polisher at a low to medium speed. Slow, overlapping passes, ensuring the pad remains flat on the surface, will help to effectively remove these lighter defects.

It’s important to work in small sections to prevent the polish from drying out and to maintain consistent pressure.

Moderate Oxidation

Paint oxidation occurs when the clear coat begins to break down due to exposure to UV rays, environmental contaminants, and harsh washing techniques. This results in a dull, chalky appearance, particularly on darker colored vehicles. Correcting moderate oxidation requires a slightly more aggressive approach than removing light swirls.For moderate oxidation, you’ll typically step up to a medium-cut polish and a more aggressive polishing pad, such as a foam or wool pad designed for cutting.

The initial stages involve thoroughly washing and decontaminating the vehicle to remove any loose dirt or grime that could cause further marring during the polishing process. Once prepped, apply the compound to the pad and work it over the oxidized areas. The key is to use moderate pressure and keep the polisher moving at a speed that allows the compound to break down and level the oxidized layer.

Multiple passes may be necessary, and it’s always advisable to test in an inconspicuous area first to gauge the effectiveness and avoid over-polishing.

Deeper Imperfections

Deeper imperfections, such as deeper scratches that you can feel with your fingernail, significant clear coat etching, or stone chips, present a greater challenge. While a dual-action polisher can significantly improve the appearance of these defects, it’s important to manage expectations. True correction of very deep scratches often requires repainting. However, a DA polisher can often reduce their visibility to a great extent.When dealing with deeper imperfections, caution is paramount.

You will likely need to employ a more aggressive cutting compound and a dedicated cutting pad, such as a firm foam or wool pad. The principle remains the same: work in small sections, keep the polisher moving, and maintain consistent pressure. However, with deeper defects, there is a higher risk of burning through the clear coat, especially on edges and contours of the vehicle.

Therefore, it is essential to:

- Assess the depth of the scratch before attempting correction. If your fingernail catches significantly, professional repair or repainting might be a better option.

- Start with the least aggressive combination that you believe will be effective and gradually increase aggression only if necessary.

- Be extremely mindful of heat buildup. Excessive heat can damage the paint.

- Use a thin layer of compound and spread it evenly across the pad and the working area before engaging the polisher.

- Work at a moderate speed and use controlled, overlapping passes.

- Wipe away residue frequently to inspect your progress and avoid compounding dry.

Hypothetical Scenario: Heavily Swirled Panel

Imagine a hood panel on a 10-year-old black car that has been subjected to years of automatic car washes, resulting in a dense network of light to moderate swirl marks. The paint appears dull and lacks depth. Objective: To remove the majority of the swirl marks and restore gloss to the hood. Tools and Supplies:

- Dual Action Polisher

- Cutting pad (e.g., a firm foam cutting pad)

- Aggressive cutting compound

- Microfiber towels for wiping

- IPA (Isopropyl Alcohol) solution for paint inspection

Process:

- Preparation: Thoroughly wash and dry the hood. Use a clay bar to remove any bonded contaminants, ensuring a smooth surface for polishing. Mask off any trim, rubber seals, and emblems to protect them from the compound and pad.

- Inspection: After masking, use a strong light source (like an LED inspection light) to thoroughly inspect the extent of the swirling. This will confirm that a cutting compound and pad are appropriate.

- Application: Apply 3-4 pea-sized drops of the cutting compound to the cutting pad. Spread the compound evenly across a small section of the hood (approximately 2×2 feet).

- Polishing: Place the pad flat on the paint surface before engaging the polisher. Start the polisher at a low speed to spread the compound, then increase to a medium speed (e.g., 4-5 on a 6-speed polisher). Work the section with slow, overlapping passes, moving the polisher horizontally and then vertically. Apply moderate, consistent pressure, ensuring the pad remains flat.

- Wipe Down and Inspection: After completing the initial passes (typically 4-6 passes per section), wipe away the compound residue with a clean microfiber towel. Use an IPA solution sprayed lightly onto a separate microfiber towel to wipe down the section. This removes any remaining polishing oils, allowing you to clearly see the paint’s condition and the effectiveness of the correction.

- Repeat and Refine: If significant swirling remains, repeat the process on that section. Once the majority of the swirls are removed, you would typically follow up with a less aggressive polish and a finishing pad to refine the finish and enhance gloss, removing any micro-marring left by the cutting compound. However, for this hypothetical scenario focused on the initial correction, we’ll assume the cutting step is the primary focus.

This systematic approach, starting with appropriate tools and a controlled technique, allows for effective correction of even heavily swirled paintwork.

Finishing and Protection

Once you have completed the polishing process, the next crucial steps involve removing any residual polish and applying a protective layer to your vehicle’s paintwork. This stage is vital for revealing the true depth of your paint’s shine and ensuring that your hard work is preserved against the elements. Proper finishing and protection will enhance the longevity and appearance of your newly polished finish.The goal of this phase is to achieve a crystal-clear surface free from any polishing compounds and then to shield that pristine surface from UV rays, environmental contaminants, and minor abrasions.

This not only maintains the aesthetic appeal but also prevents premature paint degradation, keeping your vehicle looking its best for longer.

Removing Polish Residue

After polishing, a thin film of polish residue is often left on the surface. This residue must be thoroughly removed to reveal the true clarity of the paint and to ensure that subsequent protection layers adhere effectively. Using the right tools and techniques will prevent scratching and streaking during this delicate removal process.It is essential to use clean, high-quality microfiber towels specifically designed for buffing and detailing.

These towels are highly absorbent and have a soft weave that lifts and traps residue without damaging the paint. Work in small sections to ensure that the residue does not dry onto the paint, making it more difficult to remove.

- Initial Wipe Down: Gently wipe away the bulk of the polish residue with a clean, plush microfiber towel. Use light, overlapping strokes.

- Detailing Spray (Optional but Recommended): Lightly mist a panel with a detailing spray or a dedicated panel wipe solution. This helps to lubricate the surface and lift any remaining stubborn residue.

- Final Buff: Immediately follow with a second, dry, clean microfiber towel. Buff the area in a separate direction to the initial wipe down, using a light touch, until the surface is completely clear and streak-free.

- Inspect Your Work: Visually inspect the panel under good lighting conditions to ensure all residue has been removed and no hazing or streaks remain.

Applying Sealant or Wax

Applying a paint sealant or wax after polishing is a critical step in protecting your vehicle’s newly restored finish. These products create a barrier on the paint’s surface, offering defense against harmful UV rays, acid rain, bird droppings, and other environmental contaminants. Furthermore, they enhance gloss and add depth to the paintwork, making it more resistant to swirl marks and light scratches.The choice between a sealant and a wax often comes down to desired longevity and ease of application.

Synthetic paint sealants generally offer longer-lasting protection, often for several months, while traditional carnauba waxes provide a warmer, deeper glow but typically require more frequent reapplication.

Paint Protection Application Methods

Different types of paint protection products require specific application methods to achieve optimal results and durability. Understanding these methods ensures an even application, maximum protection, and a superior finish.

Applying Paint Sealants

Paint sealants are synthetic polymers designed to bond with the paint surface, creating a durable, protective layer. They are typically applied using foam applicators or microfiber applicator pads.

- Preparation: Ensure the paint surface is completely clean, dry, and free of any polish residue. Work in a shaded area, as sealants can dry too quickly in direct sunlight, leading to application issues.

- Application: Apply a thin, even coat of sealant to a small section of the vehicle at a time. Use back-and-forth or circular motions with your applicator pad, ensuring complete coverage without applying excessive pressure.

- Curing Time: Allow the sealant to haze over according to the manufacturer’s instructions. This curing time is crucial for the product to bond with the paint.

- Buffing Off: Once hazed, gently buff off the sealant residue with a clean, plush microfiber towel. Use a separate, dry towel for the final buff to achieve a high-gloss finish.

Applying Carnauba Wax

Carnauba wax, derived from the leaves of the carnauba palm, is prized for its natural beauty and deep gloss. It is often applied with foam applicators or microfiber pads.

- Preparation: Similar to sealants, ensure the paint is clean, dry, and residue-free. Work in the shade to prevent premature drying.

- Application: Apply a very thin layer of wax to a small section. Many detailers prefer to use a light buffing motion, either straight-line or gentle overlapping circles, to spread the wax evenly. Over-application can lead to excessive buffing and potential hazing.

- Drying/Curing: Allow the wax to dry to a haze. The time required can vary depending on temperature and humidity, but it should feel slightly tacky to the touch when ready to be removed.

- Buffing Off: Using a clean, soft microfiber towel, gently wipe away the dried wax. Flip the towel frequently to ensure you are always buffing with a clean surface.

Applying Spray Waxes and Sealants

Spray-on products offer a quick and easy way to add a layer of protection and gloss. They are ideal for maintenance washes or as a topper for existing protection.

- Preparation: Ensure the vehicle is clean and dry. These products can be applied to wet or dry surfaces depending on the specific product.

- Application: Mist a small section of the panel with the spray product.

- Spreading: Immediately spread the product evenly with a clean microfiber towel.

- Buffing: Follow with a second, dry microfiber towel to buff the surface to a shine.

Common Mistakes and Troubleshooting for Beginners

Embarking on your dual action polishing journey is exciting, and like any new skill, it comes with a learning curve. Recognizing common pitfalls can significantly smooth this process, ensuring you achieve excellent results without damaging your vehicle’s paintwork. This section aims to equip you with the knowledge to identify and rectify frequent errors, turning potential frustrations into learning opportunities.Understanding the common mistakes is the first step toward mastering dual action polishing.

Many beginners encounter similar challenges, from improper pad and compound selection to technique-related issues. By addressing these proactively, you can build confidence and achieve a professional finish more efficiently.

Pad Stalling and Uneven Correction

Pad stalling occurs when the polishing pad stops rotating or significantly slows down, often due to excessive pressure or working in a confined area. This can lead to uneven correction, leaving swirl marks or a hazy finish. Uneven correction, in general, means that some areas of the paint have been polished more aggressively than others, resulting in a patchy appearance.To prevent pad stalling, maintain consistent, light to moderate pressure.

Allow the machine to do the work; don’t force it. When working on curves or edges, adjust your angle and pressure accordingly. For uneven correction, ensure you are using consistent movements across the panel and overlapping your passes by about 50%.

Paint Damage and Over-Polishing

One of the most feared outcomes for new users is paint damage, which can manifest as clear coat removal, burning through the paint, or creating deep scratches. This is often a result of using too much pressure, the wrong combination of pad and compound, or working on a single spot for too long.To avoid paint damage, always start with the least aggressive combination of pad and compound and test in an inconspicuous area.

Gradually increase aggressiveness only if necessary. Never dwell on one spot; keep the polisher moving in controlled, overlapping passes. Regularly inspect the paint’s surface as you work to gauge the correction level.

Incorrect Pad and Compound Pairing

Using a pad that is too aggressive for the paint defect, or pairing a heavy-cutting compound with a finishing pad, can lead to unwanted results. A compounding pad with a light polish might not offer enough cutting power, while a finishing pad with a heavy compound can easily mar the paint.The key here is to understand the hierarchy of abrasives and pads.

Start with a less aggressive combination and only escalate if the paint defect requires it. Always follow a more aggressive polishing step with a less aggressive one to refine the finish.

Working in Direct Sunlight or Hot Surfaces

Polishing in direct sunlight or on a hot surface can cause the polish to dry out too quickly. This makes it difficult to work with, can lead to streaking, and increases the risk of burning the paint as the product and pad generate heat.Always ensure the vehicle is cool to the touch and out of direct sunlight before you begin polishing.

Working in a shaded area or during cooler parts of the day is ideal. If you must work in less-than-ideal conditions, work in smaller sections and keep the polisher moving to prevent heat buildup.

Troubleshooting Common Problems

Addressing issues as they arise is crucial for a successful polishing session. Here’s a table outlining common problems and their recommended solutions:

| Common Problem | Recommended Solution |

|---|---|

| Pad stalling or skipping | Reduce pressure, ensure consistent movement, avoid excessive pressure on edges and curves. Check that the pad is clean and free of dried product. |

| Uneven paint correction (swirls, hazing) | Ensure consistent, overlapping passes (50% overlap). Maintain even pressure across the panel. Use a consistent speed for the machine. |

| Polish drying too quickly or streaking | Work in smaller sections. Keep the polisher moving. Avoid direct sunlight and hot surfaces. Use a spritz of detail spray to rehydrate the surface if needed. |

| Excessive dust from compound | Use a damp pad (lightly misted). Clean pads frequently. Ensure you are using the correct amount of product – not too much. |

| Residue left after wiping off polish | Ensure all product is fully worked out. Wipe with a clean, high-quality microfiber towel. If residue persists, a light mist of detail spray can help lift it. |

| Feeling vibrations or machine judder | Check pad centering and attachment. Ensure the backing plate is clean and free of debris. A worn pad or backing plate could also be the cause. |

Visualizing the Process: Pad and Polish Application

Applying polish to your dual-action polisher’s pad and then to the paint surface is a critical step that requires careful observation. Understanding what to look for visually will significantly improve your results and help you achieve a flawless finish. This section will guide you through the visual cues to watch for during this stage of the polishing process.

Polish Application to the Pad

When applying polish to your chosen pad, the goal is to achieve an even distribution without overloading it. This ensures the polish works effectively across the paint surface and prevents excessive product waste. Observing the pad’s saturation and the polish’s consistency will help you determine the correct amount to use.

The ideal amount of polish to apply to a pad is typically about the size of a nickel or a quarter, depending on the polish viscosity and pad size. You want enough to cover a small working section of the paint, but not so much that it drips or splatters.

Ideal Polish Spread Pattern

As you begin to work the polish on the paint surface with your dual-action polisher, the spread pattern provides valuable feedback about how the product is performing. Observing this pattern helps you ensure you’re covering the entire working area evenly and efficiently.

The polish should initially appear as distinct lines or ribbons on the paint surface. As you move the polisher, these lines will begin to break down and spread. The goal is to work the polish until these lines disappear and the surface takes on a consistent, slightly hazy appearance.

Understanding the Haze

The “haze” that appears during the polishing stage is a key indicator that the polish is breaking down and doing its work. It’s not a sign of damage but rather the product transforming as it abrades and refines the paint surface. Learning to recognize and interpret this haze is essential for effective polishing.

The haze signifies that the abrasives within the polish are being worked down to their final, finer stage. This is when the paint surface is being refined, and minor imperfections are being removed. The haze should be uniform across your working section. If you notice dry spots or areas where the haze dissipates too quickly, it may indicate that the polish has broken down prematurely or that your working speed needs adjustment.

The appearance of a consistent, uniform haze is the visual cue that the polish has reached its optimal working state and is actively refining the paint surface.

As you continue to work the polish, the haze will gradually become more transparent. The goal is to work the polish until it becomes almost completely clear, indicating that the abrasives have done their job and the polish is no longer actively cutting or refining the paint. Overworking the polish after it has cleared can lead to reduced effectiveness and potentially create new micro-marring.

Advanced Techniques and Next Steps

Once you’ve gained confidence with the fundamental polishing process, you’ll naturally want to elevate your skills to achieve truly show-stopping results. This section explores advanced techniques to refine your finish and provides guidance on tackling more challenging areas of your vehicle, along with avenues for continuous improvement.

Achieving a Flawless Finish

Attaining a flawless finish is a meticulous process that builds upon basic polishing. It involves an obsessive attention to detail, understanding the subtle interactions between pad, compound, and paint, and employing techniques that minimize any residual imperfections.

- Layering Polishes: For the ultimate clarity and depth, consider a multi-stage polishing process. This typically involves starting with a more aggressive compound to remove deeper defects, followed by a finer polish to refine the surface and enhance gloss. Each stage removes the micro-marring left by the previous one.

- Illuminating the Surface: A good lighting setup is crucial. Use LED swirl finders, detailing lights, or even a bright flashlight held at an oblique angle to the paint surface. This allows you to meticulously inspect your work in real-time, identifying any missed spots or hazing before moving on.

- Judicious Use of IPA Wipe Downs: After each polishing step, a diluted Isopropyl Alcohol (IPA) solution (typically 15-50%) is essential to remove polishing oils. These oils can fill in minor imperfections, giving a false sense of perfection. The IPA wipe down reveals the true state of the paint.

- Pad Cleaning and Maintenance: Keeping your pads clean and in optimal condition is paramount. Regularly clean pads during the polishing process by using a pad brush or compressed air. Damaged or clogged pads will not perform effectively and can introduce new defects.

- Working in Small Sections: Even with advanced techniques, working in smaller, manageable sections ensures thoroughness. This allows you to maintain consistent pressure and pad rotation, preventing overheating and ensuring all areas receive adequate attention.

Complex Body Panel Navigation

Navigating curved and complex body panels requires adaptability and a nuanced approach to maintain consistent results. The key is to adjust your technique to the panel’s contours without compromising the polishing action.

- Pad Angle and Pressure Adjustment: On highly curved surfaces like fenders or door pillars, you’ll need to adjust the angle of the polisher. Instead of keeping the pad perfectly flat, allow it to follow the curve. Maintain light, consistent pressure, allowing the machine to do the work. Avoid digging the edge of the pad into the paint.

- Edge Work and Recesses: For tight edges and recessed areas, consider using smaller polishing pads or even hand-polishing with foam applicators and a suitable polish. Dual action polishers, especially with larger pads, can struggle to reach these areas effectively and can potentially cause damage if not used carefully.

- Swivel and Pivot Motion: On rounded panels, a slight swivel or pivot motion with the polisher can help the pad conform to the surface. This is different from the typical back-and-forth or cross-hatch pattern and requires a gentle, controlled movement.

- Using Different Backing Plates: For very intricate areas, a smaller backing plate can be beneficial. This allows for the use of smaller pads, which are more maneuverable and less likely to make contact with surrounding trim or edges.

Further Learning and Practice

The journey of mastering paint correction is ongoing. Continuous learning and dedicated practice are the cornerstones of becoming proficient with your dual action polisher.

- Online Resources and Forums: The detailing community is vast and generous with its knowledge. Websites, YouTube channels, and dedicated detailing forums are invaluable resources for observing techniques, learning from others’ experiences, and asking specific questions.

- Detailing Courses and Workshops: For structured learning and hands-on guidance, consider attending professional detailing courses or workshops. These often provide expert instruction and the opportunity to practice on various paint types and conditions under supervision.

- Practice on Salvage Panels: Before working on your prized vehicle, consider practicing on spare body panels from a scrapyard or old car parts. This allows you to experiment with different pads, compounds, and techniques without the risk of damaging your own paint.

- Experiment with Different Products: As you gain experience, don’t be afraid to try different brands and types of compounds and polishes. Each has its own characteristics, and understanding how they perform will broaden your capabilities.

- Document Your Progress: Take before-and-after photos and notes on your polishing sessions. This documentation helps you track your improvement, identify what worked well, and remember specific techniques for future reference.

Final Review

As we conclude our exploration of how to use a dual action polisher for the first time, remember that practice and patience are your greatest allies. By understanding the tool, preparing diligently, and applying the techniques discussed, you are well-equipped to tackle paint imperfections and restore your vehicle’s luster. This journey into paint correction is not just about achieving a beautiful finish; it’s about gaining confidence and a deeper appreciation for your car’s appearance, opening the door to further learning and advanced detailing endeavors.