Embarking on the journey of car care often leads to discovering innovative techniques that significantly enhance the cleaning process. One such method that has revolutionized how enthusiasts and professionals alike approach vehicle maintenance is the touchless pre-wash utilizing a foam cannon. This approach not only promises a superior clean but also prioritizes the integrity of your vehicle’s paintwork by minimizing physical contact.

This comprehensive guide will illuminate the intricacies of mastering the foam cannon for a touchless pre-wash. We will explore its fundamental principles, the essential tools and supplies required, and a step-by-step process for setup and application. Furthermore, we will delve into understanding foam consistency, post-wash procedures, maintenance, and advanced techniques to elevate your car detailing game. Prepare to transform your car washing routine into an efficient and highly effective ritual.

Introduction to Touchless Pre-Wash with a Foam Cannon

A touchless pre-wash is a revolutionary approach to cleaning your vehicle, prioritizing the removal of loose contaminants before any physical contact is made with the paintwork. This method significantly reduces the risk of introducing swirl marks and scratches that can occur during traditional washing processes. By leveraging the power of specialized cleaning solutions and advanced application tools, a touchless pre-wash sets the stage for a safer and more effective overall detailing experience.The foam cannon plays a pivotal role in this technique.

It is a device designed to atomize a mixture of water and car wash soap into a thick, clinging foam. This foam is then applied generously over the entire vehicle’s surface. The primary purpose of this foam is to encapsulate and lift dirt, grime, road salt, and other abrasive particles away from the paint, allowing them to be safely rinsed off without the need for scrubbing.There are several primary advantages to adopting a touchless pre-wash over traditional methods.

These include a substantial reduction in the risk of paint damage, a more efficient removal of heavy road film and debris, and a cleaner surface for subsequent washing steps. This approach is particularly beneficial for vehicles that are frequently exposed to harsh road conditions or for those who are meticulous about maintaining a flawless paint finish.Performing a touchless pre-wash is most effective under specific conditions to maximize its benefits and ensure safety.

Ideal Conditions for Performing a Touchless Pre-Wash

To achieve the best results with a touchless pre-wash, several environmental and vehicle-related factors should be considered. These conditions help the foam to adhere effectively, break down contaminants, and minimize the risk of premature drying, which could leave residue.

- Temperature: The ideal ambient temperature for a touchless pre-wash is between 50°F (10°C) and 80°F (27°C). Temperatures outside this range can affect the foam’s performance. In very cold weather, the water and soap mixture may not foam properly or could freeze, while in excessively hot weather, the foam can dry too quickly, leaving streaks and making rinsing more difficult.

- Sunlight: Direct sunlight should be avoided whenever possible. Washing in direct sun can cause the foam to dry rapidly on the surface, leading to water spots and making it harder to rinse away cleanly. Performing the wash in a shaded area or during cooler parts of the day (early morning or late evening) is highly recommended.

- Vehicle Surface Temperature: Similar to ambient temperature, the surface of the vehicle itself should not be excessively hot. If the car has been driven recently or parked in the sun, it’s advisable to let it cool down before applying the foam. A cool surface allows the foam to dwell longer and work more effectively.

- Wind Conditions: Moderate to light winds are acceptable, but strong winds can blow the foam away from the vehicle, reducing its dwell time and coverage. Excessive wind can also carry dust and debris onto the wet surface, counteracting the purpose of the pre-wash.

- Water Availability: A reliable source of clean water is essential for both mixing the foam solution and for the final rinse. Ensure you have enough water to thoroughly rinse all the foam and loosened dirt from the vehicle.

Essential Equipment and Supplies

To achieve an effective touchless pre-wash with a foam cannon, having the right equipment and supplies is paramount. This section will guide you through the necessary components, detailing each element to ensure you are well-prepared for a superior car cleaning experience. Understanding the function and specifications of each item will help you make informed choices.The process of creating a rich, clinging foam relies on a synergistic combination of your pressure washer, a quality foam cannon, and a specifically formulated car wash soap.

Water quality also plays a significant role in the final foam consistency and effectiveness. We will explore each of these aspects in detail.

Foam Cannon Setup Components

A functional foam cannon setup requires several key components working in harmony to produce the desired thick foam. Each part contributes to the overall efficiency and effectiveness of the pre-wash.The core of the system is the foam cannon itself, which attaches to a pressure washer. This cannon is designed to mix the concentrated soap solution with water at a specific ratio to create foam.Here is a list of the essential components for a foam cannon setup:

- Pressure Washer: A machine that provides pressurized water, typically ranging from 1000 to 4000 PSI. The flow rate (GPM) also influences foam quality.

- Foam Cannon: The device that attaches to the pressure washer wand and mixes soap and water. It features an adjustable nozzle and a soap reservoir.

- Car Wash Soap: A specialized, high-foaming soap designed for use with foam cannons.

- Water Source: A reliable supply of clean water, ideally from a hose connected to a tap.

- Bucket (optional but recommended): For rinsing the foam cannon or for a two-bucket wash method if needed.

Suitable Car Wash Soaps for Foam Cannons

The type of car wash soap used is critical for generating a thick, clinging foam that effectively lifts dirt and grime. Not all car wash soaps are created equal, and using the wrong product can lead to poor foam quality or even damage to your vehicle’s paintwork. Foam cannon soaps are formulated with specific surfactants that create a stable, rich lather.When selecting a car wash soap for your foam cannon, consider the following characteristics:

- High-foaming capabilities: The soap should be designed to produce abundant, dense foam.

- pH-neutral formulation: This ensures the soap is safe for all automotive surfaces, including paint, trim, and wheels, and won’t strip existing wax or sealant layers.

- Biodegradability: Environmentally friendly options are increasingly available and recommended.

- Concentration: Many foam cannon soaps are highly concentrated, meaning a little goes a long way, offering good value.

- Lubricity: Good soaps provide excellent lubrication, reducing the risk of scratching during the rinsing process.

Examples of reputable car wash soaps known for their foaming properties include brands like Chemical Guys Mr. Pink Super Suds Shampoo, Adam’s Car Wash Shampoo, and Griot’s Garage Best of Show Wash. Always check the product’s label to confirm it is suitable for foam cannon use.

Importance of Water Quality for the Pre-Wash Solution

The quality of the water used in your foam cannon mixture significantly impacts the consistency and effectiveness of the foam produced. Hard water, which contains high mineral content, can interfere with the soap’s ability to lather properly, resulting in a thinner, less effective foam.Using de-ionized or filtered water is highly recommended for several reasons:

- Improved Foaming: De-ionized water lacks the minerals that inhibit soap lathering, leading to a richer, more stable foam.

- Spot-free rinsing: Using de-ionized water for the final rinse after the foam wash helps prevent water spots, as there are no dissolved minerals left behind to dry on the surface.

- Enhanced Soap Performance: The absence of minerals allows the soap’s surfactants to work more efficiently, maximizing their cleaning power.

While a dedicated de-ionizer might be an investment, using filtered water from a household filter can also offer improvements over standard tap water.

Different Types of Foam Cannons

Foam cannons vary in their design and how they connect to pressure washers, influencing their performance and ease of use. Understanding these differences helps in choosing the right cannon for your specific needs.The primary distinction lies in how they connect to the pressure washer and their internal mechanisms for mixing soap and water.Here are the main types of foam cannons:

- Guns (or Handheld Foam Cannons): These are the most common type, attaching directly to the wand of a pressure washer. They typically feature a plastic or brass body with a mesh filter and an adjustable nozzle for foam density.

- Foam Generators (or Foam Lances): These are more professional-grade units that often connect to the pressure washer’s outlet hose. They are generally larger and designed for higher-volume use, producing a denser foam.

Within the gun category, you will find variations in the quality of materials used (brass is generally more durable than plastic), the size of the soap reservoir, and the fineness of the mesh filter, which impacts foam consistency. Many foam cannons also come with different “ின்” (quick-connect) fittings to ensure compatibility with various pressure washer brands.

Checklist of All Required Items

To ensure you have everything necessary for a successful touchless pre-wash using a foam cannon, it is beneficial to have a comprehensive checklist. This will prevent last-minute rushes and ensure a smooth detailing process.This checklist covers all the essential equipment and supplies discussed previously.

| Item | Description | Quantity |

|---|---|---|

| Pressure Washer | Minimum 1000 PSI, with appropriate GPM for foam generation. | 1 |

| Foam Cannon | Compatible with pressure washer, with adjustable nozzle. | 1 |

| Car Wash Soap | High-foaming, pH-neutral, designed for foam cannons. | 1 bottle |

| Water Source | Garden hose connected to a tap. | 1 |

| Water Filter (optional) | For improving water quality. | 1 |

| Bucket (optional) | For rinsing or separate soap application. | 1-2 |

| Microfiber Towels | For drying after rinsing. | Several |

Setting Up Your Foam Cannon

Proper setup is crucial for achieving the best results from your foam cannon. This section will guide you through the assembly, soap-to-water ratio, and connection to your pressure washer, ensuring a leak-free and effective pre-wash experience. A well-prepared foam cannon will deliver a thick, clinging foam that lifts dirt and grime from your vehicle’s surface.

Foam Cannon Assembly

Assembling your foam cannon is a straightforward process, typically involving a few key components. Most foam cannons consist of a bottle, a foaming nozzle or head, and an adapter that connects to your pressure washer wand.To assemble the foam cannon:

- Begin by ensuring all parts are clean and free from debris.

- Attach the foaming nozzle head securely to the threaded neck of the foam cannon bottle. Hand-tighten to avoid cross-threading.

- If your foam cannon uses a separate adapter for your specific pressure washer, ensure it is firmly screwed onto the inlet of the foam cannon head.

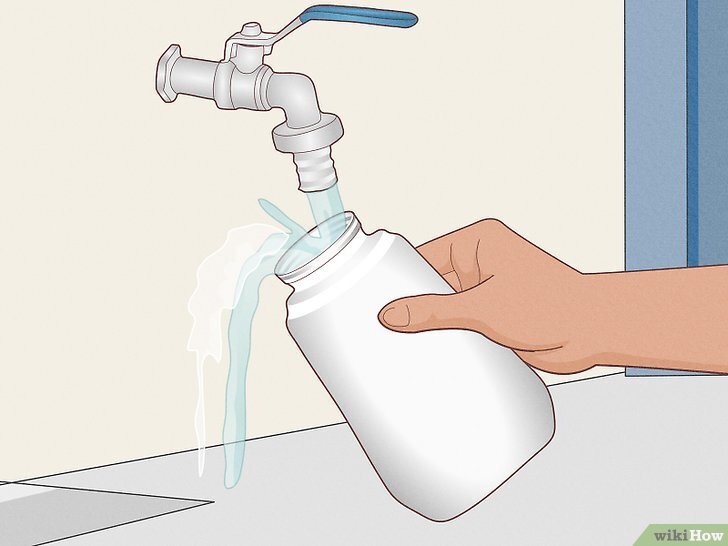

Mixing the Soap and Water Ratio

The effectiveness of your foam cannon heavily relies on the correct dilution of car wash soap and water. Too little soap will result in thin, watery foam, while too much can be wasteful and difficult to rinse. The ideal ratio creates a rich, dense foam that adheres to the vehicle.The recommended ratio for most high-quality car wash soaps is typically between 1:10 and 1:30 (soap to water).

Always refer to the specific instructions on your car wash soap’s packaging, as formulations can vary.A common starting point for a balanced foam is:

For every 1 ounce of car wash soap, add 10 to 15 ounces of warm water.

Using warm water can help the soap to emulsify better, leading to a richer foam.

Attaching the Foam Cannon to a Pressure Washer

Connecting your foam cannon to the pressure washer is the final step in the setup process. This connection needs to be secure to prevent leaks and ensure consistent pressure.The attachment method will vary slightly depending on the type of quick-connect fittings your pressure washer and foam cannon utilize. Common fittings include 1/4-inch or 3/8-inch quick-connect systems.To attach the foam cannon:

- Ensure your pressure washer is turned off and the trigger is released to relieve any residual pressure.

- Identify the outlet on your pressure washer wand where the foam cannon will connect.

- Align the adapter on the foam cannon with the fitting on the pressure washer wand.

- Push the foam cannon adapter firmly into the wand fitting until it clicks into place, indicating a secure connection. For threaded connections, screw the adapter onto the wand until it is snug.

Ensuring a Secure and Leak-Free Connection

A secure connection is vital for both safety and efficiency. Leaks can not only waste your valuable soap solution but can also create a mess and reduce the foam cannon’s performance.Tips for a secure and leak-free connection:

- Always check the O-ring or rubber seal within the foam cannon adapter. A damaged or missing O-ring is a common cause of leaks. Replace it if necessary.

- Ensure the connection is fully seated. You should hear or feel a distinct click with quick-connect fittings.

- If using threaded fittings, do not overtighten, as this can damage the threads. Tighten until firm, then give a slight extra turn.

- Test the connection by briefly engaging the pressure washer trigger. If you notice any drips or sprays, immediately release the trigger and re-secure the connection.

- Regularly inspect your foam cannon and pressure washer fittings for any signs of wear or damage.

The Touchless Pre-Wash Application Process

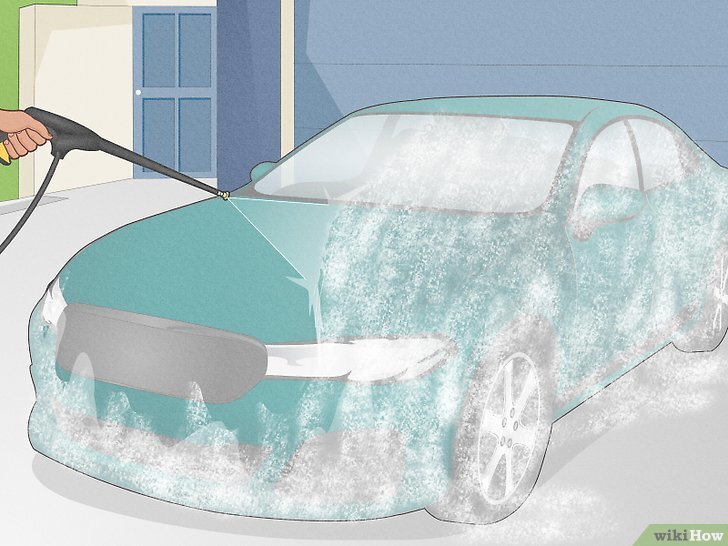

Embarking on the touchless pre-wash with your foam cannon is a crucial step in achieving a pristine vehicle finish without introducing unnecessary risks of scratching. This process leverages the power of a thick, clinging foam to lift and encapsulate dirt, grime, and road salt, preparing the surface for a safe and effective contact wash or even a fully touchless rinse.

Proper application ensures maximum contact time and coverage, allowing the cleaning agents to work efficiently.The success of your touchless pre-wash hinges on a systematic approach to foam application. By understanding the nuances of coverage, dwell time, and rinsing, you can significantly enhance the effectiveness of this preparatory stage. This section will guide you through the precise techniques to master the application process, ensuring a superior clean and a protected finish.

Foam Application Technique for Even Coverage

Achieving an even layer of foam across the entire vehicle is paramount for effective cleaning. The goal is to create a consistent blanket of suds that adheres to all surfaces, allowing the cleaning solution to break down contaminants uniformly. This prevents streaks and ensures that all areas receive adequate attention.The application should begin at the lowest point of the vehicle and systematically move upwards.

This method ensures that the foam on the lower sections, which typically accumulate the most dirt and road film, is not immediately washed away by the foam applied to the upper sections. This allows for maximum dwell time on the dirtiest areas.

Coverage Strategy: Bottom-Up Application

Starting from the bottom of the vehicle and working your way up is the recommended strategy for applying foam. This approach ensures that the foam has sufficient time to dwell on the most heavily soiled areas, such as the lower rocker panels, wheel wells, and lower doors, which are often subjected to the harshest road grime.The process involves holding the foam cannon at a consistent distance from the surface, typically 12-18 inches, and sweeping in a methodical pattern.

Overlap each pass slightly to guarantee complete coverage without missing any spots. For instance, when foaming the side of the car, start at the very bottom and move the lance upwards, covering the entire panel before moving to the next.

Foam Density and Spray Pattern Adjustment

Your foam cannon allows for customization to suit various cleaning needs and preferences. Adjusting the foam density and spray pattern ensures optimal performance and efficient use of your cleaning solution.The foam cannon typically has two main adjustment points:

- Air-to-Solution Ratio Knob: This knob controls the amount of air mixed with the cleaning solution. Turning it clockwise generally increases the air, resulting in a thicker, richer foam. Turning it counter-clockwise reduces air, leading to a thinner, more watery foam.

- Nozzle Adjustment (if applicable): Some foam cannons have an adjustable nozzle that allows you to change the spray pattern from a concentrated stream to a wider fan. For pre-washing, a wider fan pattern is generally preferred for broader coverage.

Experiment with these settings to find the perfect balance for your specific cleaning task. A thicker foam is ideal for clinging to vertical surfaces and maximizing dwell time, while a slightly thinner foam can be useful for rinsing or covering larger, flatter areas more quickly.

“Thicker foam offers superior cling time, allowing for deeper penetration and breakdown of stubborn contaminants.”

Best Practices for Foam Dwell Time

The dwell time, or the period the foam is left on the vehicle’s surface, is critical for its effectiveness. It allows the cleaning agents in the foam to loosen and lift dirt without drying out. The ideal dwell time varies depending on environmental conditions and the type of surfaces being treated.Generally, a dwell time of 5-10 minutes is recommended. However, it is crucial to avoid letting the foam dry on the surface, especially in direct sunlight or warm temperatures.

If the foam begins to dry prematurely, rinse the section immediately.

Consider these factors for optimal dwell time:

- Temperature: In cooler temperatures, you can allow slightly longer dwell times. In hot, sunny conditions, reduce the dwell time to prevent drying.

- Surface Type: While most exterior surfaces can handle the recommended dwell time, be cautious with delicate trim or rubber seals.

- Dirt Level: Heavily soiled vehicles may benefit from a slightly longer dwell time, but always monitor for drying.

Thorough Vehicle Rinsing After Foam Application

Once the foam has had sufficient time to work, a thorough rinse is essential to remove the encapsulated dirt and the cleaning solution. This step is critical to prevent any residue from being left behind, which could lead to water spots or streaks.Use a pressure washer or a strong stream from a garden hose to rinse the vehicle. Begin rinsing from the top of the vehicle and work your way downwards.

This ensures that the loosened dirt and foam are washed away efficiently, preventing them from re-depositing on already rinsed areas.

Follow these rinsing guidelines:

- Top-Down Approach: Always start rinsing from the roof and work your way down.

- Adequate Water Pressure: Ensure sufficient water pressure to effectively dislodge the foam and contaminants.

- Complete Coverage: Rinse all areas thoroughly, including door jambs, wheel wells, and under the vehicle.

- Check for Residue: Visually inspect the vehicle for any remaining foam or dirt.

Procedural Steps for Applying Foam

To ensure a systematic and effective foam application, follow this step-by-step procedure:

- Prepare the Foam Cannon: Fill the foam cannon’s reservoir with the appropriate dilution of your chosen car wash soap and water, as per the manufacturer’s instructions. Attach the reservoir securely to the cannon.

- Adjust Settings: Dial in your desired foam density and spray pattern using the adjustment knobs on the foam cannon.

- Begin Application (Bottom-Up): Start at the lowest point of the vehicle (e.g., rocker panels) and work your way upwards in sweeping motions.

- Systematic Coverage: Apply foam to one section at a time, ensuring even coverage and slight overlap between passes. Pay close attention to areas that accumulate more dirt.

- Work Around the Vehicle: Continue applying foam to the entire vehicle, moving from one panel to the next in a consistent direction.

- Address Wheels and Tires: Foam the wheels and tires thoroughly to break down brake dust and road grime.

- Monitor Dwell Time: Allow the foam to dwell for the recommended time (typically 5-10 minutes), being mindful of temperature and sunlight to prevent drying.

- Rinse Thoroughly (Top-Down): Once the dwell time is complete, begin rinsing the vehicle from the roof downwards, using strong water pressure to remove all foam and loosened dirt.

- Inspect and Re-foam if Necessary: Visually inspect the vehicle for any missed spots or remaining residue. If necessary, re-foam and rinse those specific areas.

Understanding Foam Consistency and Performance

Achieving the perfect foam is crucial for an effective touchless pre-wash. The quality of the foam directly impacts its ability to lift and encapsulate dirt, making the rinsing process more efficient and reducing the risk of scratching your vehicle’s paintwork. Understanding the factors that influence foam consistency and how to interpret its performance will help you optimize your washing results.The ideal foam should be thick, rich, and cling to the vehicle’s surface, allowing it to dwell and break down contaminants.

This is not just about aesthetics; it’s about maximizing the cleaning power of your chosen soap. By fine-tuning your setup and observing the foam’s behavior, you can ensure you’re getting the most out of your touchless pre-wash.

Factors Influencing Foam Quality

Several variables play a significant role in the density and cling-factor of your foam. Adjusting these elements can dramatically improve your pre-wash results.

- Soap Concentration: The ratio of car wash soap to water is paramount. Too little soap will result in thin, watery foam, while too much can lead to excessive suds that are difficult to rinse and may even leave residue. Always refer to the soap manufacturer’s dilution recommendations.

- Water Pressure: The incoming water pressure to your pressure washer influences how well the soap is agitated and mixed with air. Higher pressure generally leads to a thicker, more stable foam, but excessive pressure can sometimes shear the foam too quickly.

- Water Hardness: Hard water, with its higher mineral content, can sometimes affect the foaming properties of soaps. Softer water generally produces better foam.

- Foam Cannon Design and Quality: Different foam cannons have varying internal mechanisms and nozzle sizes, which affect the air-to-liquid mixture. Higher-quality cannons with well-designed air inlets and adjustable nozzles typically produce superior foam.

- Temperature: Both the ambient temperature and the temperature of the water can influence foam stability. Colder temperatures can sometimes lead to less stable foam.

Troubleshooting Thin or Watery Foam

Experiencing foam that looks more like soap bubbles in a bath than a thick blanket on your car can be frustrating. Fortunately, most issues are easily rectified.

- Increase Soap Concentration: If your foam is too thin, try increasing the amount of car wash soap in your foam cannon’s reservoir. Start with a small increase and test the results.

- Adjust Water/Air Mixture: Most foam cannons have an adjustable nozzle or air intake. Experiment with closing the air intake slightly or adjusting the nozzle to a finer spray pattern to encourage thicker foam.

- Check Water Pressure: Ensure your pressure washer is operating at its recommended PSI for the foam cannon. If your pressure is too low, it may not be sufficient to create a dense foam.

- Use a Quality Car Wash Soap: Not all soaps are formulated to create thick foam. Ensure you are using a soap specifically designed for foam cannons and touchless pre-washing.

- Consider Water Source: If you consistently have issues with foam quality, especially in an area with very hard water, you might consider using distilled or deionized water for your foam cannon mixture.

Characteristics of Foam Types

The way foam behaves on your vehicle provides clues about its effectiveness. Understanding these differences helps you assess your wash’s progress.

Thick, Clinging Foam

This is the ideal scenario for a touchless pre-wash. Thick foam has a dense, creamy texture that adheres to the vertical surfaces of your vehicle.

- Appearance: Resembles shaving cream or whipped cream. It should not run off immediately.

- Performance: Excellent at lifting and encapsulating dirt, grime, and road film. Its prolonged contact time allows the cleaning agents to break down contaminants effectively.

- Benefit: Maximizes the “touchless” aspect by providing a substantial barrier that loosens debris before any physical contact is made.

Thin, Sheeting Foam

This type of foam is less dense and tends to run off the vehicle’s surface more quickly. While it still offers some cleaning benefit, it’s generally less effective for a thorough pre-wash.

- Appearance: Looks more like soapy water or weak bubbles that quickly dissipate.

- Performance: Offers minimal dwell time and less ability to lift and suspend heavy contaminants. It might rinse away lighter dust but struggles with tougher grime.

- Reason for Occurrence: Often a result of incorrect soap concentration, insufficient water pressure, or a foam cannon not properly calibrated.

Visual Cues of Proper Foam Coverage and Effectiveness

Observing the foam as it covers your vehicle offers immediate feedback on the quality of your pre-wash.

- Uniform Coverage: The foam should blanket the entire vehicle in an even layer, with no significant gaps or thin spots. This ensures all surfaces are treated.

- “Melting” Effect: As the foam dwells, you should observe a gradual “melting” or sheeting effect as it breaks down. This indicates that the soap is actively working to lift dirt. The dirt and grime should become visible within the dissolving foam.

- Color Change: The foam may change color as it absorbs dirt, often becoming gray or brown. This is a positive sign that it is effectively lifting contaminants from the paintwork.

- Surface Dwell Time: The foam should remain on the surface for at least a few minutes (typically 3-5 minutes, depending on conditions) before rinsing. If it disappears too quickly, it’s not performing optimally.

Post-Foam Wash Procedures

Following the application of foam, the next critical step is the thorough rinsing process. This phase is essential to remove all loosened dirt, grime, and, most importantly, any soap residue from your vehicle’s surface. A proper rinse ensures a clean slate for subsequent washing stages and prevents potential issues like water spots or streaks.The rinsing technique employed is as crucial as the foam application itself.

A systematic approach guarantees that all areas of the vehicle are reached and effectively cleaned. This not only enhances the aesthetic appeal of your car but also contributes to the longevity of its paintwork by removing abrasive particles.

Rinsing Technique for Complete Soap Residue Removal

Achieving a spotless finish after the foam pre-wash requires a meticulous rinsing strategy. The goal is to dislodge and wash away all the suspended dirt and soap particles that the foam has encapsulated. This is best accomplished with a steady flow of water, paying close attention to all contours and crevices of the vehicle.

The primary technique involves using a pressure washer or a strong stream from a garden hose. Start at the highest point of the vehicle and work your way downwards. This gravity-assisted flow ensures that the dirty water cascades down, cleaning each subsequent section without re-contaminating previously rinsed areas. Ensure you overlap your passes slightly to avoid missing any spots.

Importance of Top-Down Rinsing

The principle of rinsing from the top down is fundamental in car washing, particularly after a foam pre-wash. This method leverages gravity to its full advantage, ensuring that all loosened contaminants are directed away from clean surfaces. By starting at the roof and progressively moving towards the lower panels, you prevent the dirty runoff from re-soiling areas that have already been rinsed.

Imagine a waterfall; the water flows downwards, carrying debris with it. Applying this to your car wash means that the water and soap residue from the roof will flow over the hood, doors, and fenders. If you were to rinse from the bottom up, you would be pushing dirty water and soap residue onto already clean upper sections, defeating the purpose of a thorough rinse and potentially leading to streaks and water spots.

Methods for Checking for Remaining Dirt or Grime

After the initial rinse, a visual inspection is crucial to confirm that all dirt and soap residue have been effectively removed. This step is often overlooked but is vital for a truly clean vehicle. A quick check can save you from encountering stubborn dirt or soap marks later in the washing process.

- Visual Inspection: Carefully examine the entire vehicle surface under good lighting conditions. Look for any remaining foam patches, streaks, or areas that appear dull or grimy. Pay special attention to panel gaps, trim edges, and around badges where dirt can accumulate.

- Touch Test: Gently run a clean, dry microfiber towel over various sections of the vehicle. If the towel picks up any dirt or feels gritty, it indicates that the rinsing was not complete in that area. This is a more sensitive method for detecting fine residues.

- Water Break Test: After rinsing, observe how water sheets off the paint. If water beads up in random patterns or leaves trails, it might suggest the presence of soap residue or a loss of the protective wax or sealant layer. A clean surface should ideally sheet water evenly.

Next Steps in the Car Washing Process After Pre-Wash

Once the foam pre-wash and thorough rinsing are complete, your vehicle is primed for the subsequent stages of the washing process. The pre-wash has effectively loosened and removed the majority of the surface contaminants, making the contact wash (if you choose to do one) much safer and more effective.

The typical next step after a successful foam pre-wash and rinse is the contact wash. This involves using a high-quality car wash soap and a wash mitt to gently agitate any remaining surface dirt. The goal here is to lift and encapsulate the final layer of grime without introducing scratches.

The touchless pre-wash with a foam cannon is designed to minimize contact, but a gentle contact wash afterward ensures a truly immaculate finish.

Following the contact wash, another thorough rinse is performed to remove all soap and loosened dirt. After the final rinse, it’s essential to dry the vehicle immediately to prevent water spots. This is typically done using plush microfiber drying towels or an air blower. If you’re applying a ceramic coating or wax, the vehicle should be completely dry and clean before proceeding to those application steps.

Foam Cannon Maintenance and Storage

Proper maintenance and storage are crucial for ensuring your foam cannon continues to perform optimally and lasts for years to come. Neglecting these steps can lead to clogs, leaks, and reduced foaming capabilities. This section will guide you through the essential practices for keeping your foam cannon in top condition.

Post-Use Cleaning Procedures

After each use, a thorough cleaning of your foam cannon is essential to prevent residue buildup and maintain its functionality. This involves disassembling key components and rinsing them to remove any remaining soap or dirt.

Follow these steps for an effective post-use cleaning:

- Empty any remaining soap solution from the bottle.

- Fill the bottle with clean, warm water.

- Attach the bottle to the foam cannon and spray the clean water through the nozzle for a minute or two. This flushes out any residual soap from the internal components and the lance.

- Disassemble the foam cannon by unscrewing the bottle and the nozzle tip.

- Rinse the bottle thoroughly with clean water and let it air dry.

- Inspect the internal mesh screen (if applicable) and the nozzle tip for any debris. Gently clean them with a soft brush or cloth if necessary. Avoid using abrasive materials that could damage the components.

- Allow all parts to air dry completely before reassembly or storage.

Proper Foam Cannon Storage

Storing your foam cannon correctly will protect it from damage and environmental factors that can degrade its performance. The goal is to keep it clean, dry, and protected from extreme temperatures.

To ensure optimal storage:

- Make sure all components are completely dry before storing. Moisture can lead to corrosion or mold growth.

- Store the foam cannon in a cool, dry place, away from direct sunlight and extreme temperatures. A garage or a dedicated storage cabinet is ideal.

- Avoid storing the foam cannon with a full bottle of soap solution, as this can put unnecessary pressure on seals and potentially lead to leaks over time.

- If possible, store the foam cannon in its original packaging or a protective bag to prevent dust accumulation and accidental damage.

Maintenance for Optimal Performance

Regular maintenance goes beyond basic cleaning and addresses potential issues before they impact your foam cannon’s performance. This includes checking for wear and tear and ensuring all connections are secure.

Key maintenance tasks include:

- Periodically inspect the O-rings and seals for any signs of cracking or wear. If they appear damaged, replace them to prevent leaks.

- Check the nozzle tip for any blockages or damage. A clean and unobstructed nozzle is vital for producing thick, rich foam.

- Ensure the connection between the bottle and the foam cannon body is secure. A loose connection can lead to leaks and reduced foam quality.

- If your foam cannon has an adjustable air-to-liquid ratio or spray pattern control, ensure these mechanisms are functioning smoothly. Lubricate them sparingly with a silicone-based lubricant if they become stiff.

Tips for Extending Foam Cannon Lifespan

By implementing a few proactive strategies, you can significantly extend the operational life of your foam cannon and continue to enjoy its benefits for many washes to come.

Consider these tips to maximize your foam cannon’s lifespan:

- Always use a high-quality car wash soap specifically designed for foam cannons. Harsh chemicals or incorrect soap ratios can damage the internal components and seals.

- Never leave soap solution in the bottle for extended periods. Empty and rinse the bottle after each use, even if you plan to use it again soon.

- Avoid dropping or mishandling the foam cannon. While durable, significant impacts can cause internal damage.

- When connecting the foam cannon to your pressure washer, ensure the connection is secure and the threads are not cross-threaded. This prevents leaks and potential damage to the fittings.

- If you notice any unusual noises or reduced foam production, address the issue promptly rather than continuing to use the cannon. Early intervention can prevent more significant problems.

Advanced Techniques and Tips

While the basic foam cannon pre-wash is effective, several advanced techniques and considerations can elevate your cleaning results, especially when dealing with specific challenges or vehicle types. Understanding the nuances of pre-wash soaps and application methods can make a significant difference in achieving a truly spotless finish.

Pre-Wash Soap Selection for Specific Cleaning Needs

The choice of pre-wash soap is paramount, as different formulations are designed to tackle various types of grime. Selecting the right soap ensures maximum effectiveness without compromising your vehicle’s protective coatings.

- pH-Neutral Soaps: These are the most versatile and safest option for general cleaning and routine maintenance. They effectively lift dirt and grime without stripping existing wax, sealants, or ceramic coatings. Ideal for vehicles that are regularly washed and don’t have heavy contamination.

- Alkaline Pre-Wash Soaps: These are more potent and designed to break down stubborn organic contaminants like insect splatters, bird droppings, and road film. While effective, they can be harsher on delicate waxes and sealants if left on for too long or used too frequently. They are best reserved for heavily soiled vehicles or specific problem areas.

- Degreasers/Solvent-Based Pre-Wash Soaps: These are the strongest options, formulated to cut through heavy grease, tar, and industrial fallout. They are typically used sparingly and with caution, as they can strip protective layers. Often best applied spot-by-spot to specific stubborn contaminants rather than as a full vehicle pre-wash.

Tackling Heavily Soiled Areas with Foam

When faced with areas of extreme dirt buildup, a standard foam application might not be sufficient. Strategic adjustments to your technique can significantly improve foam’s ability to lift these stubborn contaminants.

- Increased Dwell Time: For heavily soiled areas, allow the foam to dwell for a slightly longer period than usual. This gives the cleaning agents more time to penetrate and break down the grime. However, always monitor the foam to prevent it from drying on the surface, which can cause water spots.

- Multiple Applications: In cases of severe contamination, a single application might not remove all the dirt. Consider applying foam to the heavily soiled area, rinsing it off, and then reapplying foam for a second pass. This layered approach can be very effective.

- Targeted Application: Instead of covering the entire vehicle, focus your foam cannon on the most affected areas. This conserves product and allows for a more concentrated cleaning action where it’s needed most.

- Gentle Agitation (if necessary): While the goal is touchless, for extremely stubborn spots that the foam alone isn’t lifting, a very gentle agitation with a soft wash mitt or a dedicated detailing brush can be employed after the foam has dwelled. This should be done with extreme care to avoid scratching.

Adapting the Foam Cannon Process for Different Vehicle Types

The principles of foam cannon pre-washing remain consistent, but minor adjustments can optimize the process for various vehicle types, ensuring thorough cleaning without damage.

- Trucks and SUVs: These larger vehicles often have more complex body lines, wheel wells, and undercarriages that accumulate dirt. Ensure thorough coverage, paying extra attention to lower panels and wheel arches where mud and road salt tend to collect. Consider a slightly longer dwell time for the lower sections.

- Motorcycles: Motorcycles require a more delicate approach due to their intricate parts and sensitive finishes. Use a pH-neutral soap to avoid damaging delicate plastics, chrome, or painted surfaces. Be mindful of electrical components and avoid direct, high-pressure spraying into sensitive areas. A gentler spray pattern might be preferred.

- Classic Cars and Highly Polished Finishes: For vehicles with delicate paintwork or extensive polishing, always opt for a pH-neutral soap and a shorter dwell time. The goal is to lift loose debris without stressing the paint. Thorough rinsing is crucial to remove all soap residue.

Effectiveness of Different Soap Dilutions for Pre-Wash

The concentration of your pre-wash soap directly impacts its cleaning power and foaming ability. Experimenting with dilutions can help you find the sweet spot for your specific needs and water conditions.

| Dilution Ratio (Product:Water) | Foam Quality | Cleaning Power | Residue Risk | Best Use Case |

|---|---|---|---|---|

| 1:3 (Concentrated) | Very thick, clings well | High | Moderate (requires thorough rinsing) | Heavily soiled vehicles, stubborn grime |

| 1:5 (Standard) | Good thickness, good coverage | Moderate to High | Low to Moderate | General pre-wash, routine cleaning |

| 1:10 (Diluted) | Lighter foam, spreads easily | Moderate | Low | Lightly soiled vehicles, maintaining coatings |

| 1:20 (Very Diluted) | Thin foam, minimal cling | Low | Very Low | Rinseless wash preparation, light dust removal |

Closing Notes

In conclusion, the foam cannon stands as a remarkable tool for achieving a pristine, touchless pre-wash, safeguarding your vehicle’s finish while effectively lifting dirt and grime. By understanding the nuances of equipment, preparation, application, and maintenance, you can consistently achieve professional-grade results. Embracing this method not only streamlines your car washing process but also contributes to the long-term preservation and beauty of your vehicle.

May your detailing endeavors be ever so foam-tastic!